Connect4HCA | 2024-2028

Connectivity for Human-Centered Automation 5.0

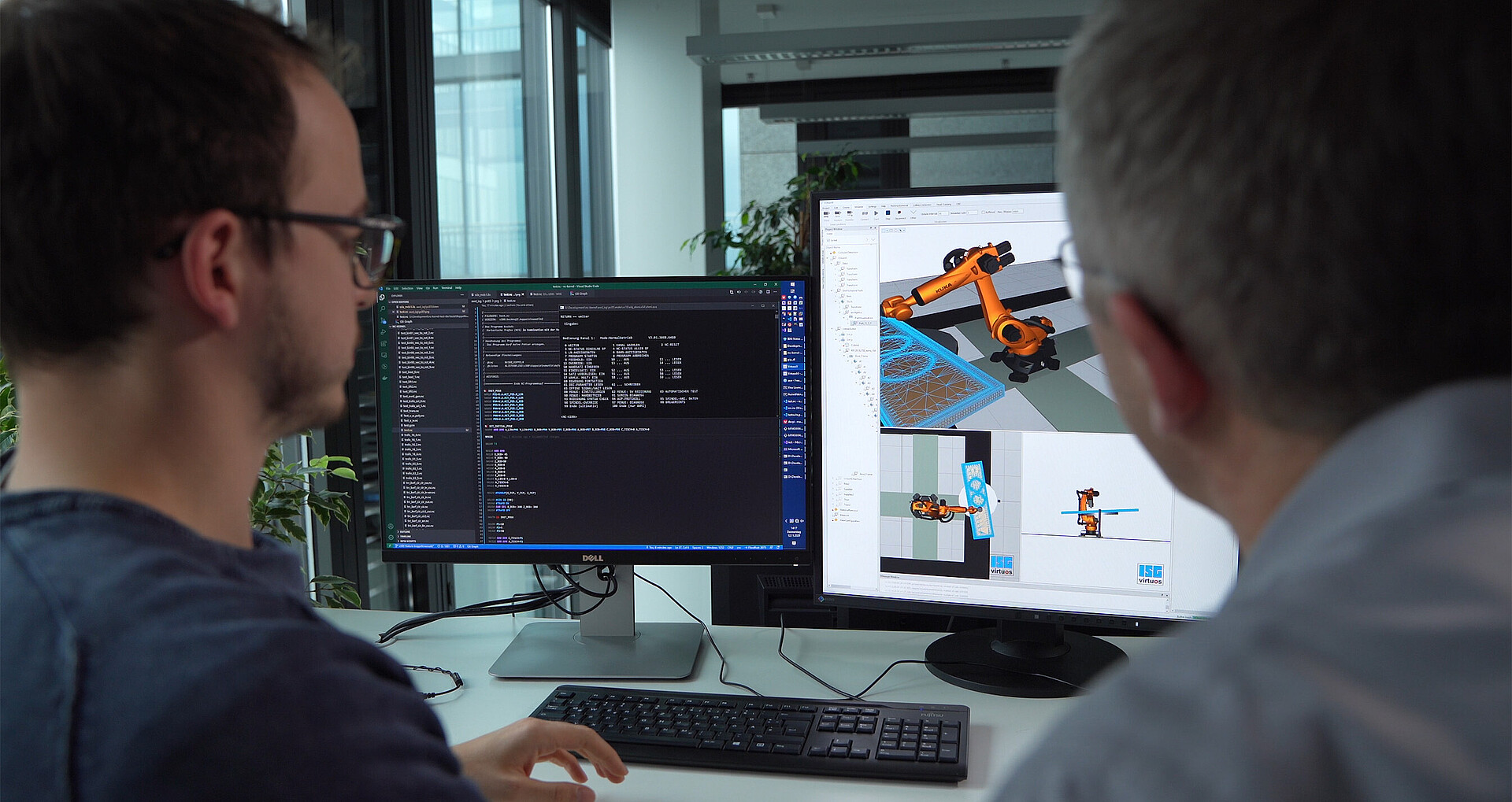

Implementation of advanced connectivity technologies and structures in production

By taking a holistic view of connectivity, the Connect4HCA project places people at the centre of industrial automation. The concept of connectivity ranges from the integration of processes, plants, production lines and locations as well as supply chains to systems and data across their lifecycles. Furthermore, the term connectivity encompasses both the interaction from technology to technology and between human and artificial intelligence. In the future, decentralised technical intelligence will shape the entire value chain along the product life cycle together with humans. To this end, a holistic demonstrator is being created as a research platform, in which connectivity is considered in several dimensions.

The project is funded by the Federal Ministry for Economic Affairs and Climate Protection on the basis of a decision by the German Bundestag.

Project partner

| Balluff GmbH | DITF - Deutsche Institute für Textil- und Faserforschung Denkendorf |

| NAiSE GmbH | Fraunhofer |

| Siemens AG | Nokia |

| Arena 2036 e.V. | Institut für Steuerungstechnik der Werkzeugmaschinen und Fertigungseinrichtungen (ISW) Universität Stuttgart |