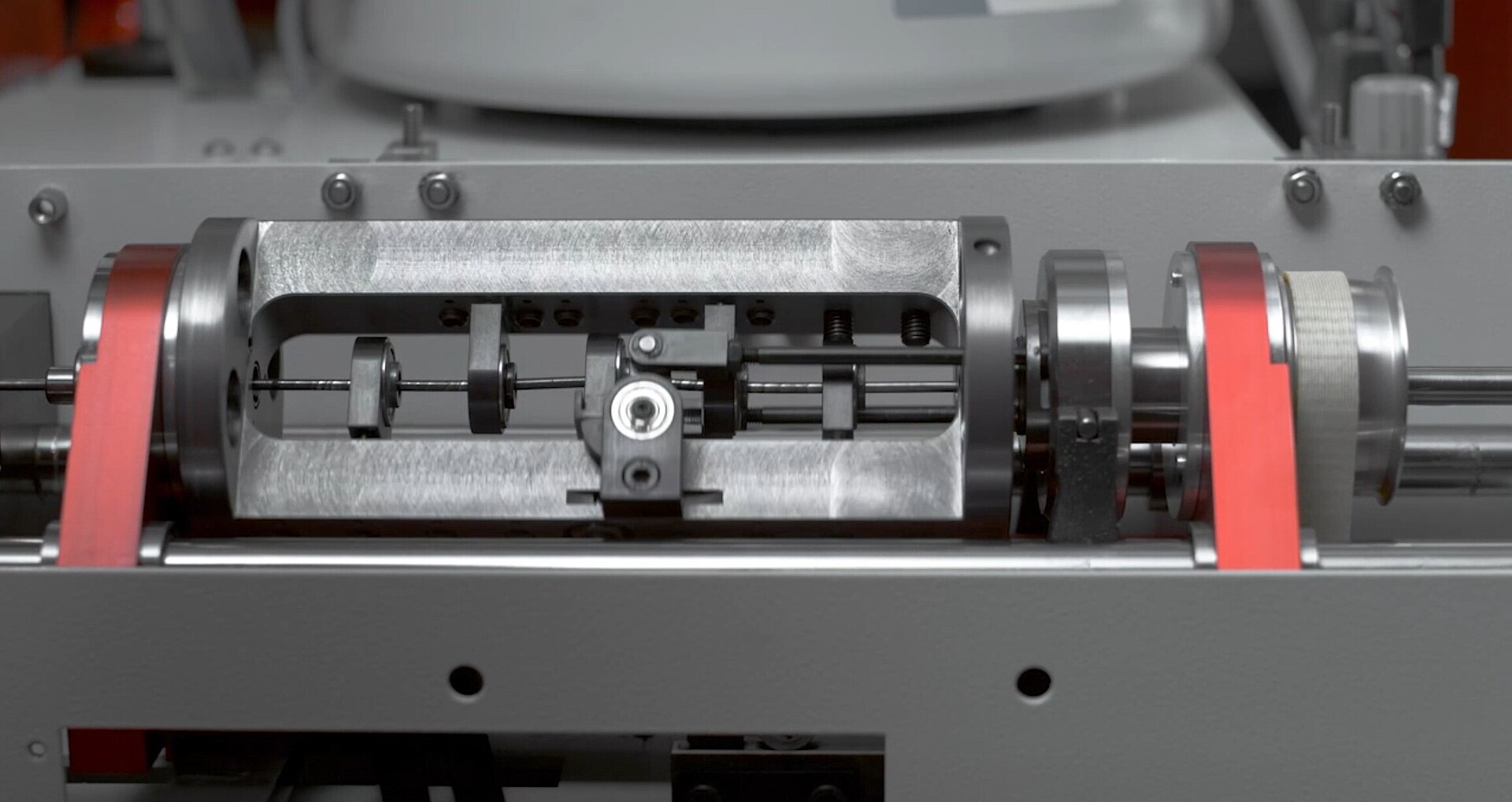

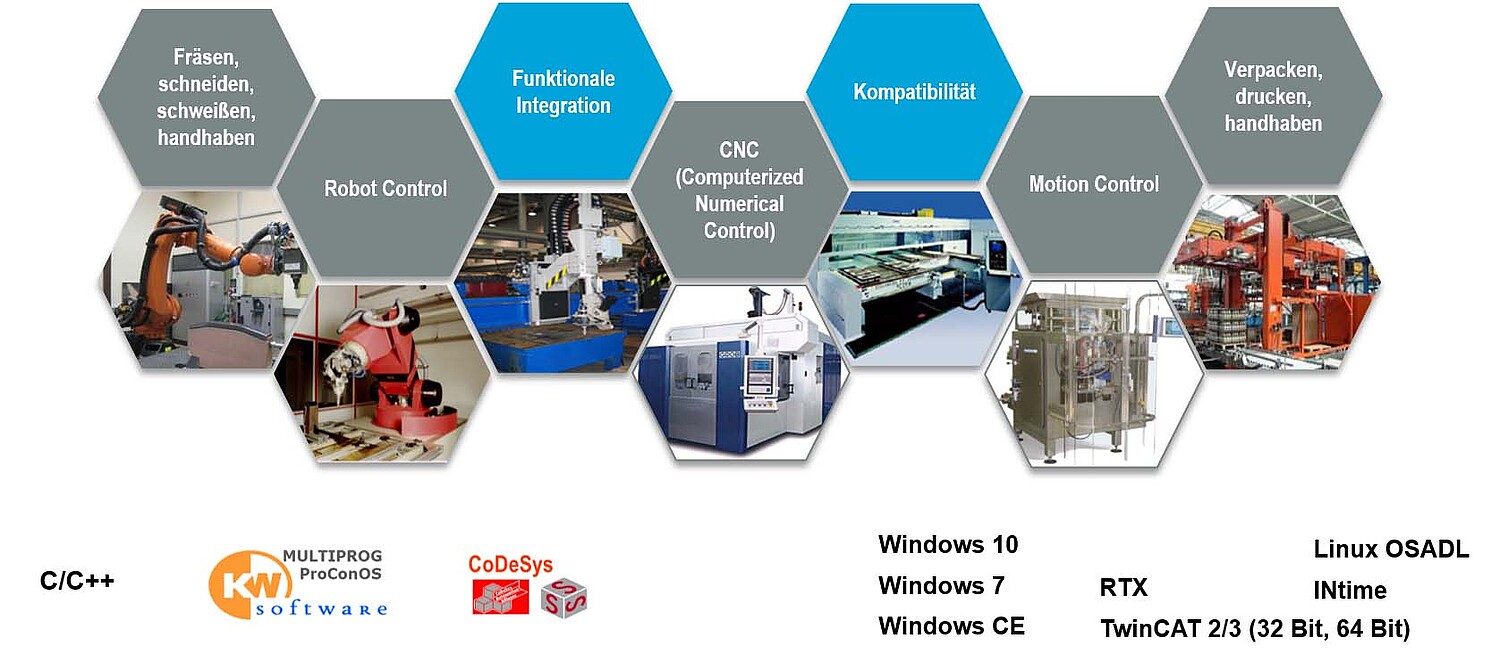

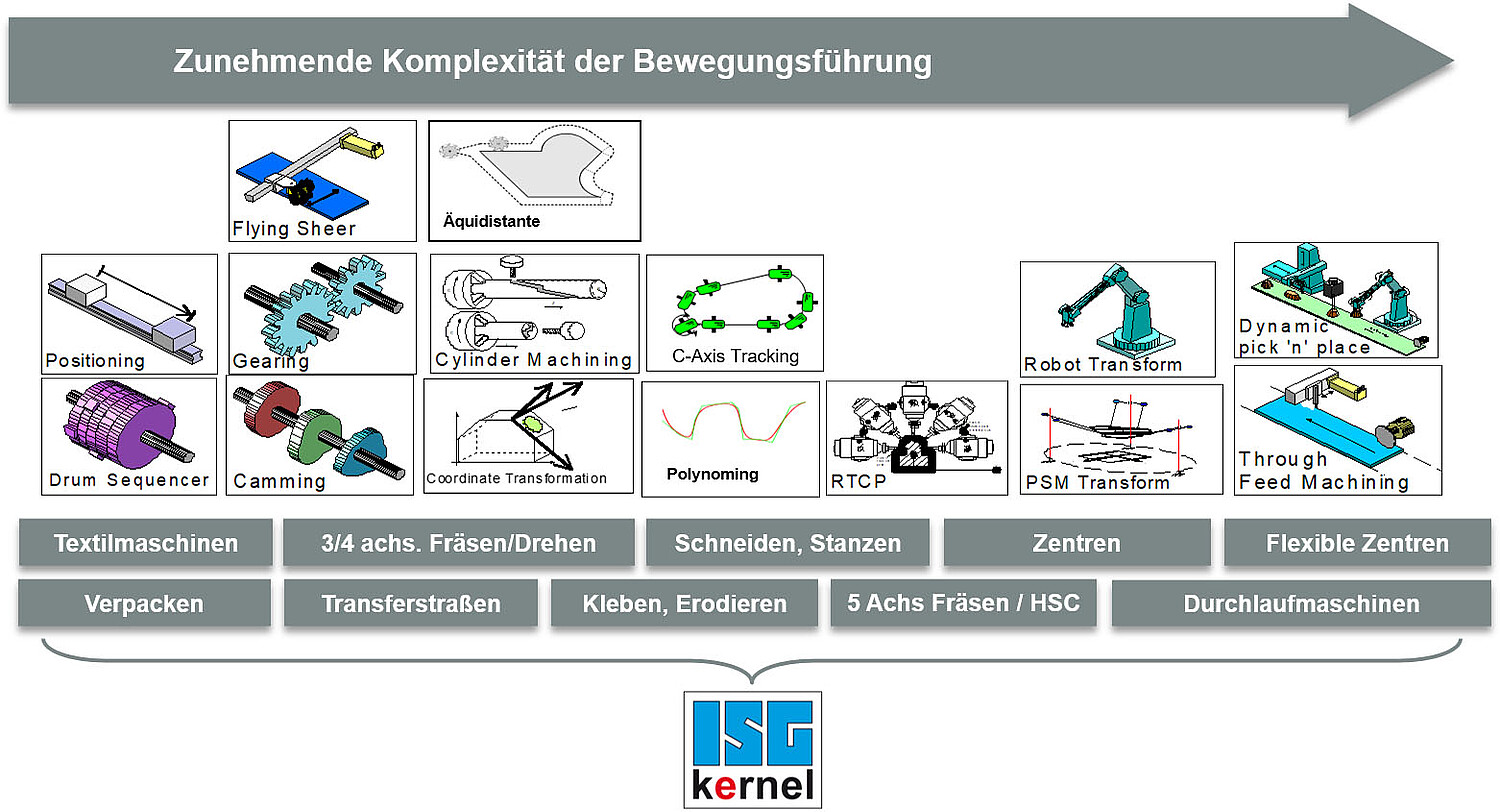

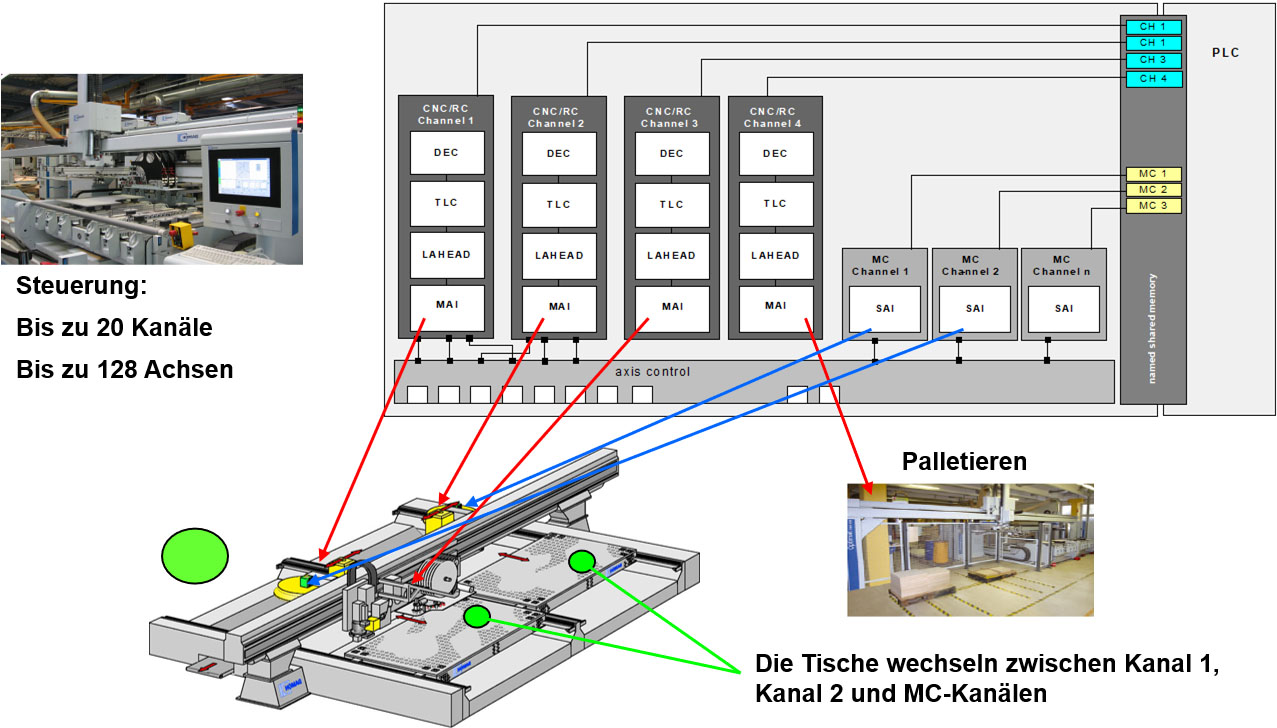

Control manufacturer

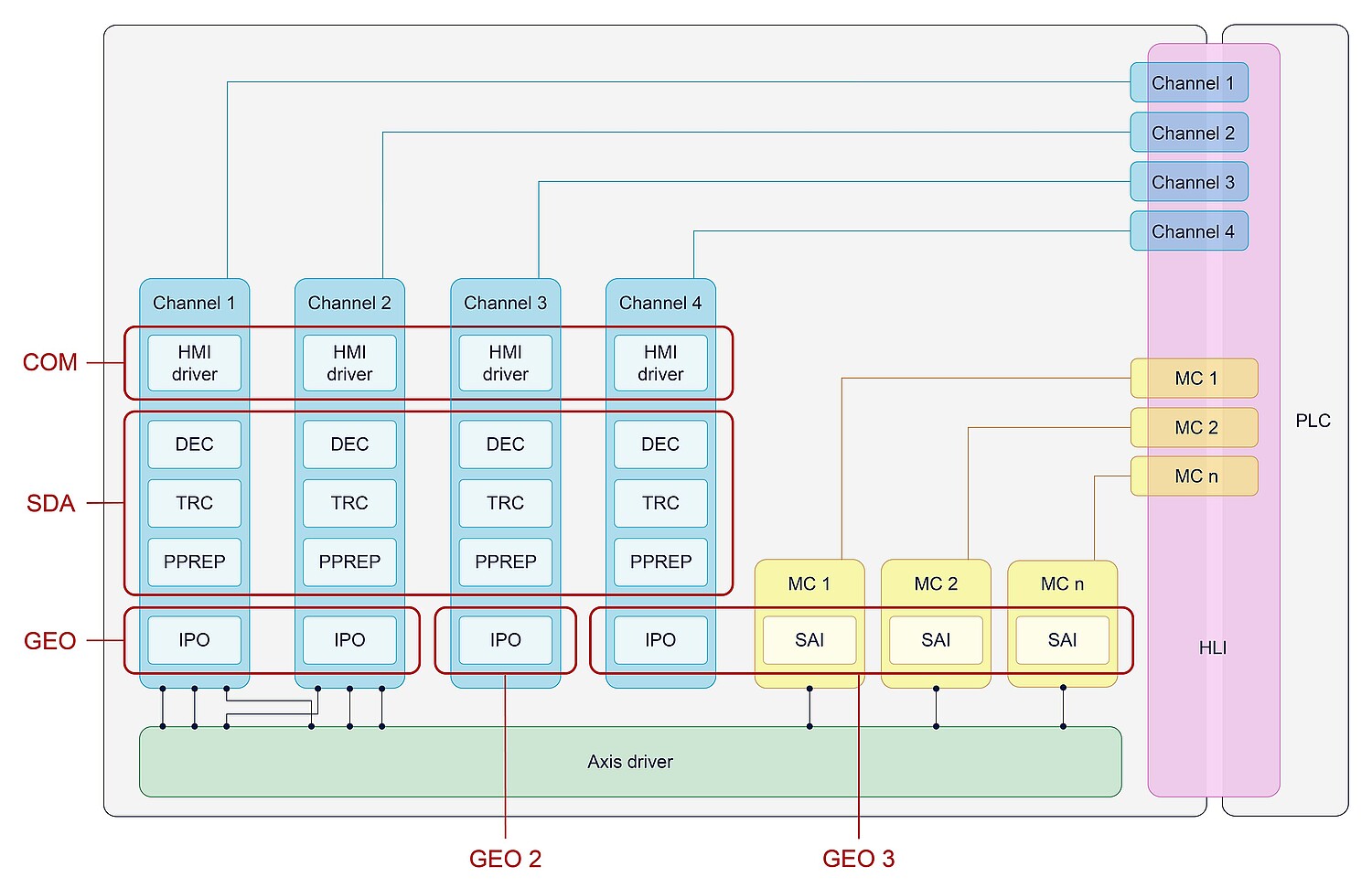

Control manufacturers are faced with the challenge of constantly advancing the functionality and performance of their controls. Especially the development of high-end functionalities (3D machining, kinematic transformations, HSC, multi-channel, compensations, collision monitoring, ...) ties up capacities and requires in-depth know-how. ISG-kernel includes many of these functionalities and, thanks to its openness and compatibility, complements existing control technology to a powerful complete system within a very short time.