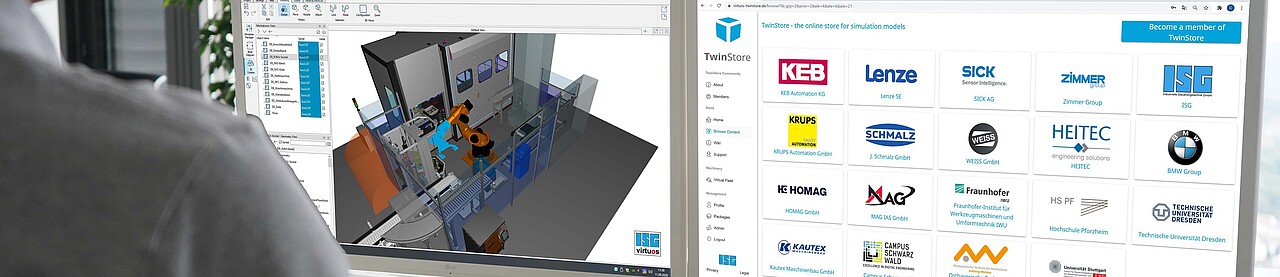

The component manufacturers presented their product catalogs to each other, which are available in the TwinStore as simulation models for virtual commissioning. As early as 2021, prefabricated simulation models could be successfully used in virtual commissioning and the modeling times of virtual machines and plants could be significantly reduced. More than 750 component models from the members of the TwinStore Community are already available in the TwinStore today and we are pleased to welcome further partners such as HEITEC, KEB, Lenze, WEISS, KRUPS Automation and Campus Schwarzwald to the community since the last summit. Together, collaboration goals have been defined for 2022 to further expand the availability of virtual product catalogs.

We are looking forward to a successful year 2022 together!

The TwinStore is an online exchange platform for simulation models of real components used for virtual commissioning of automation solutions and control systems. Virtual commissioning enables an overall test before the real commissioning in order to test and optimize a plant at any time. The individual simulation models are provided directly by the component manufacturers or simulation specialists for use in simulation projects of the machine and plant manufacturer or system integrator. The individual product catalogs offer a wide selection of digital twins that enable the assembly of customer-specific systems. Among the digital twins are virtual components and assemblies such as drive technology, sensor technology, robot systems, conveyor technology and gripping systems.

For more information on the component manufacturers and their product catalogs, please visit the TwinStore at www.virtuos-twinstore.de/about.