Description

Task

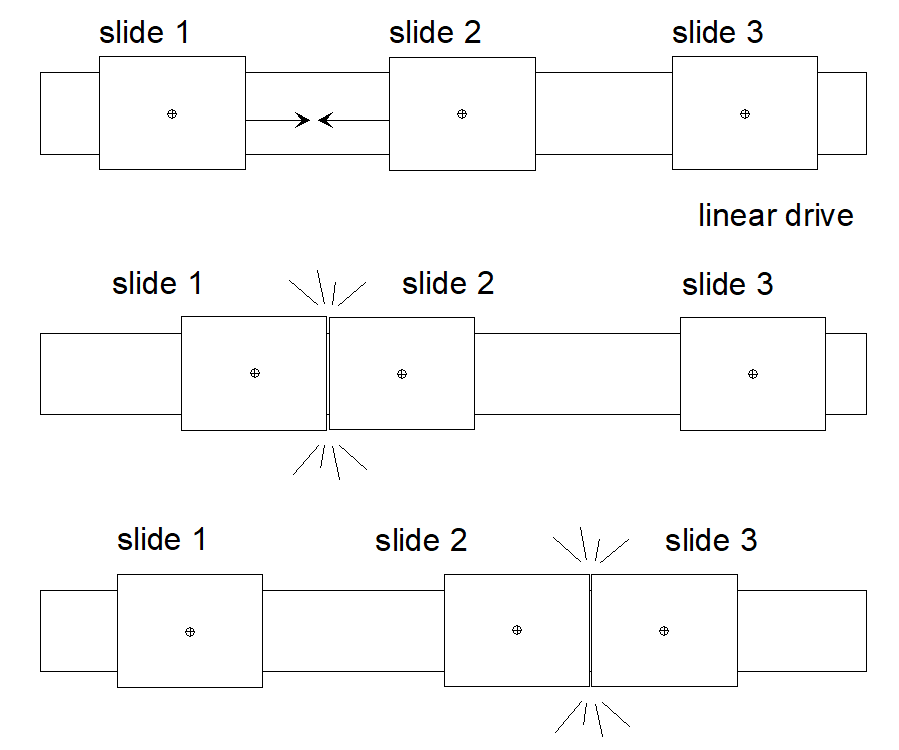

When collision monitoring is used, the position command values of an axis pair generated in the CNC are monitored.

If the distance between two positions undershoots the minimum permitted value with regard to the deceleration distance required for stopping,

- the axes stop immediately depending on the specified dyn. data and

- the CNC outputs the message P-ERR-70092.

After CNC RESET, the two axes must be positioned apart from each other.

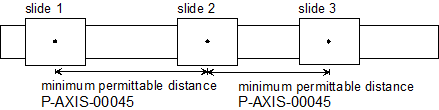

Two axes for which the distance is monitored are referred to as a collision pair.

Several collision pairs may be formed.

Besides machines with linear drive, collision monitoring is also used for machine with strut kinematics to monitor column slides for collisions.

Attention

If the axes are shut down when a collision is detected, the programmed contour is normally exited.

Configuration

In the parameter P-AXIS-00015 (achs_mode) the 0x8000 bit is set for the two axes in a collision pair. The collision monitor is then active.

Additional data must be set for collision monitoring in one of the two axes of a collision pair. Normally the following inputs are set in the second axis of a collision pair, referred to as the master axis:

- In P-AXIS-00043 (coll_check_ax_nr) the logical axis number of the collision partner.

- In P-AXIS-00045 (coll_offset) the minimum permitted distance between slide reference points.

This type of configuration is no longer recommended: Due to downwards compatibility, two axes can be configured as collision partners. In this case the two collision distances P-AXIS-00045 (coll_offset) have the same value.

If the collision axes are in different CNC channels, the parameter P-AXIS-00044 (coll_decelerate_chan) can force a stop in the two channels if a collision axis reports a drive error.

Notice

The corresponding axes must first be referenced. Only then is the collision monitor active.

Axis deceleration for collision monitoring

By default the value of P-AXIS-00008 (a_max) is used for collision monitoring to calculate deceleration distances and stop the axes if a collision is detected.

The parameter P-AXIS-00267 (coll_use_a_emergency) can be used to change this deceleration to the value defined in P-AXIS-00003 (a_emergency).

Deceleration distance monitoring

The current velocity of an axis results from:

vt = (sollwtn - sollwtn-1) / TA

where: | vt | current velocity |

The minimum deceleration distance results from the deceleration set for collision monitoring by:

- P-AXIS-00008 (a_max),

- P-AXIS-00267 (coll_use_a_emergency),

- P-AXIS-00003 (a_emergency)

and the current velocity at:

sbrems = ½ (vt2/acoll)

where: | sbrems | Deceleration distance |