Ramp time weighting (G132/G133/G134/G233/G338/G339)

Syntax of weightings for ramp time: | ||

G132 <axis_name>. | Axis-specific ramp time weighting, weighting for specific axes in [%], only acts on feed blocks G1/G2/G3. | modal |

G133=.. | Axis group-specific ramp time weighting with G01, G02, G03, weighting for all axes in [%] | modal |

G134=.. | Axis group-specific weighting of geometrical ramp time, weighting for all axes in [%] | modal |

G233=.. | Axis group-specific ramp time weighting with G00, weighting for all axes in [%] | modal |

Weightings for ramp times in feedhold: | ||

G338 <axis_name>. | Axis-specific ramp time weighting with feedhold, weighting for specific axes in [%] [as of V3.1.3079.16] | modal |

G339=.. | Axis group-specific ramp-time weighting with feedhold, weighting for all axes in [%] [as of V3.1.3079.16] | modal |

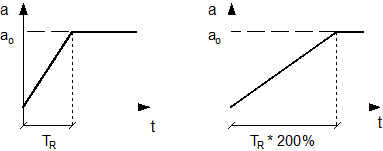

These ramp times can be influenced by a percentage change in the corresponding default ramp times. The G132/G133/G233 functions can change the ramp time of axis acceleration with a non-linear slope [2]-1. (If the slope is linear, the acceleration curve is step-shaped (see figure in Section Jerk-limiting slope)

The G134 function can change the geometrical ramp time of a non-linear slope (P-AXIS-00199).

The parameters for acceleration ramp times for the up-gradation and down-gradation of acceleration are P-AXIS-00196 and P-AXIS-00195 respectively, and for the up-gradation and down-gradation of deceleration, the parameters are P-AXIS-00198 and P-AXIS-00197 respectively.

When P-CHAN-00097 is set, the feedhold parameter list is used for the deceleration process. In this case, the deceleration of the feedhold ramp P-AXIS-00081 by a percentage change using G338/G339.

When the function is programmed with G132/G133/G134/G233/G338/G339, all axes which are not programmed or not yet programmed are set to 100%. Every additional selection of these functions, irrespective of previous programming, refers to 100%. This means that geometrical data processing always weights default values with the percentage value. Therefore, 50% programmed twice in succession means the setting is made to 50% and not to 25%.

Attention

After an axis exchange, the G132/G333 weighting factors are reset for all axes involved to 100%.

Notice

Ramp time weighting does not act on single axis motions e.g. homing, manual more an independent axes.

Programing Example

Ramp time weighting (G132/G133/G134/G233/G338/G339)

N10 G132 X200 | ;Axis-specific weighting of ramp time ;Ramp time of X axis is increased by 200% |

N20 G01 F1000 X100 | ;Linear interpolation |

N30 G132 Y50 | ;Ramp time of Y axis is decreased by 50% ;Ramp time of X axis remains at 200% |

N40 Y100 | ;Linear interpolation |

N50 G133 = 100 | ;Axis group-specific weighting of ramp time ;G01,G02,G03 ramp times of all axes to 100% |

N60 G134 = 50 | ;Axis group-specific weighting of ramp time ;Geometrical ramp time of all axes to 50% |

N70 G233 = 80 | ;Axis group-specific weighting of ramp time ;G00 ramp times of all all axes to 80% |

N80 G00 X200 | ;Rapid traverse |

N90 G338 X150 | ;Axis-specific weighting of ramp time ;with feedhold. Ramp time of X axis is increased to ;150%. |

N100 G339 = 200 | ;Axis group-specific weighting of ramp time ;with feedhold. Ramp time of all axes is increased to ;200%. |

Special feature: | |

N50 G133 = 100 X10 Y20 | ;With G133/ G134/G233/G339 axis positions can ;also be programmed in the same block! |

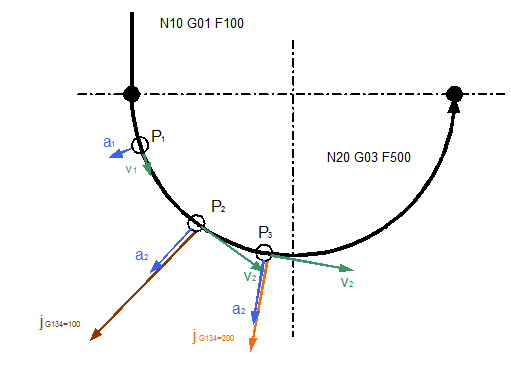

The figure below shows the influence of G134 on acceleration perpendicular to the path (centrifugal acceleration a1--> a2) with increasing feed (v1 --> v2) during circular motion (P1 --> P2).

If the change in centrifugal acceleration is reduced by increasing the G134 ramp time, acceleration is smoother and target acceleration a2 is not reached until point P3.