Measuring with external measuring hardware

Interface for external measuring hardware | |

Description | The CNC informs the PLC about the initialisation, start or end of a measurement run via the external measuring interface. In order to use a switchable measuring probe, EXT_PROBE_WITH_DRIVE must be selected, otherwise PLC_EXT_LATCH_CTRL. (see P-AXIS-00516 or [PROG//Extended programming]) |

Data type | LcControlExtLatchControl |

Special features | This interface is only used to control the activation and deactivation of external measuring hardware.

|

Access | PLC writes please_rw + done_w |

ST path | gpAx[axis_idx]^.ext_latch_control |

Command | |

ST element | .please_rw |

Description | When please_rw is set, the CNC signals to the PLC to prepare, activate or deactivate the external measuring hardware since a measurement run was started, aborted or terminated. |

Data type | BOOL |

Value range | [TRUE, FALSE] |

Special features | Consumption data item |

Access | The CNC refreshes the data of the measuring interface only if this element is FALSE. After a refresh, the CNC sets this element to TRUE after the element done_w was set to FALSE. The PLC reads the data of the measuring interface if this element has the value TRUE. After the data is transferred, the PLC sets the value to FALSE. |

Parameter | |||

ST element | .ext_latch_order_r | ||

Description | The CNC signals to the PLC in this datum the required measurement parameters such as activate/deactivate the measuring function or the number of the measurement input. | ||

Data type | HLI_EXT_LATCH_ORDER | ||

Access | PLC is reading | ||

Acknowledgement | |||

ST element | .done_w | ||

Description | By setting the element done_w to TRUE, the PLC signals to the CNC that the measuring job was executed. The measuring hardware is then ready, activated or deactivated. | ||

Data type | BOOL | ||

Value range | [TRUE, FALSE] | ||

Special features | Consumption data item | ||

Access | The PLC sets the value to TRUE if the measuring order was executed. The CNC sets the value to a FALSE before a new command. | ||

Measuring order data | |||

Description | In this parameter, the CNC signals to the PLC whether the measuring hardware is to be prepared, activated or deactivated. In addition, the CNC informs the PLC of the measurement channel to be used and the relevant measurement edge. | ||

Data type | HLI_EXT_LATCH_ORDER | ||

ST path | gpAx[axis_idx]^.ext_latch_control.ext_latch_order_r | ||

Access | PLC is reading | ||

Measuring order identifier | |||

Description | ID of measuring order to be executed. | ||

ST element | .order_id | ||

Data type | UDINT | ||

Value range | Constant | Meaning | |

HLI_EXT_LATCH_PREPARE_PROBE | The measuring hardware must be prepared | ||

HLI_EXT_LATCH_ENABLE_PROBE | Start of measurement run, the measuring hardware must be activated. | ||

HLI_EXT_LATCH_DISABLE_PROBE | The measurement run was terminated or aborted by reset.

| ||

Access | PLC is reading | ||

Number of probing input | ||

Description | In this data item, the CNC signals to the PLC the input to be used for measuring (see P-AXIS-00517) | |

ST element | .input | |

Data type | DINT | |

Value range | Probing input 1 – 255 | |

Access | PLC is reading | |

Relevant measurement edge | ||

Description | In this data item, the CNC signals to the PLC the relevant measurement edge (rising/falling) to be used for measuring (see P-AXIS-00518) | |

ST element | .edge | |

Data type | UDINT | |

Value range | Constant | Meaning |

HLI_MEAS_SIGNAL_LOW_ACTIVE | The measured value is to be detected on the falling edge. | |

HLI_MEAS_SIGNAL_HIGH_ACTIVE | The measured value is to be detected on the rising edge.

| |

Access | PLC is reading | |

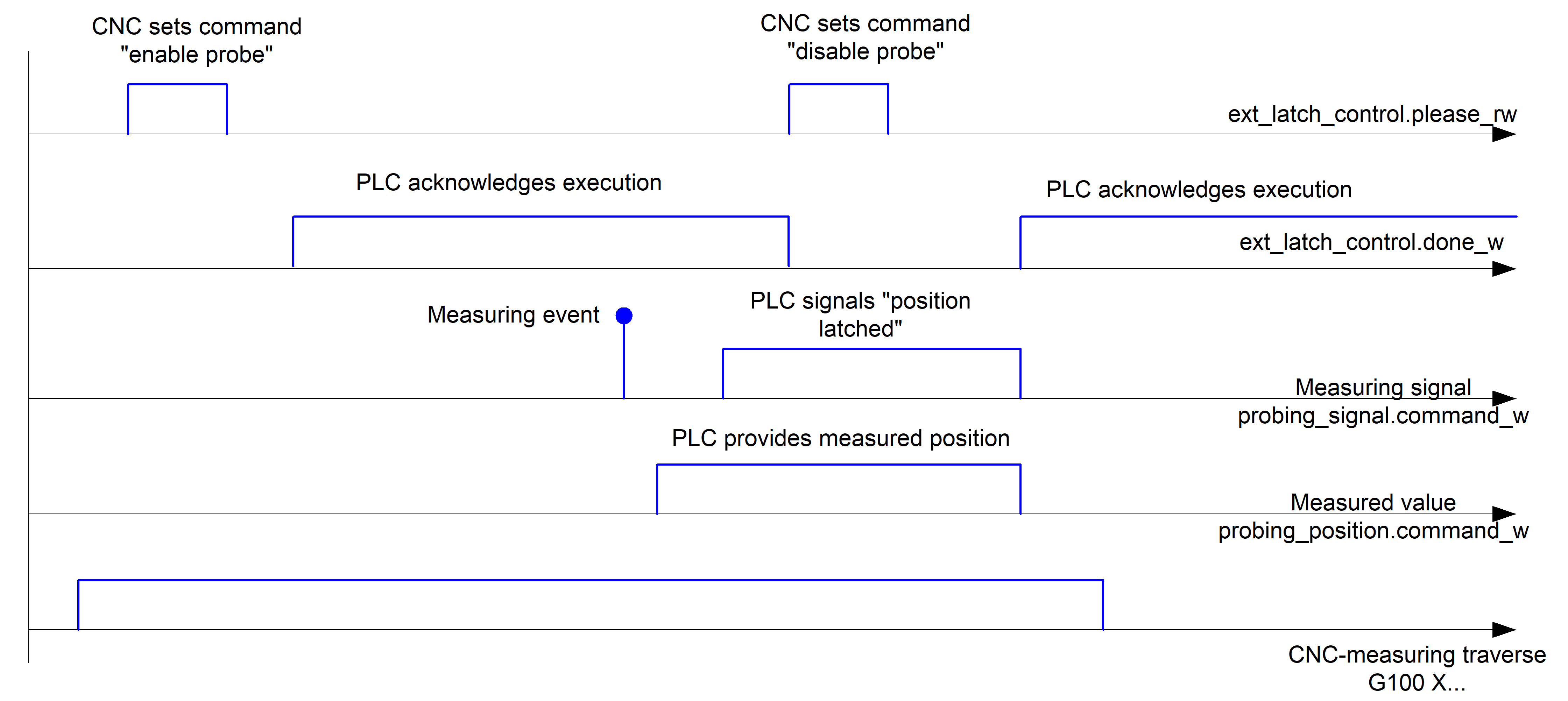

Signal profile with PLC_EXT_LATCH_CTRL

The block diagram below shows an example of the signal profile of the control units ext_latch_control, probing_signal and probing_position during a measurement process with external hardware:

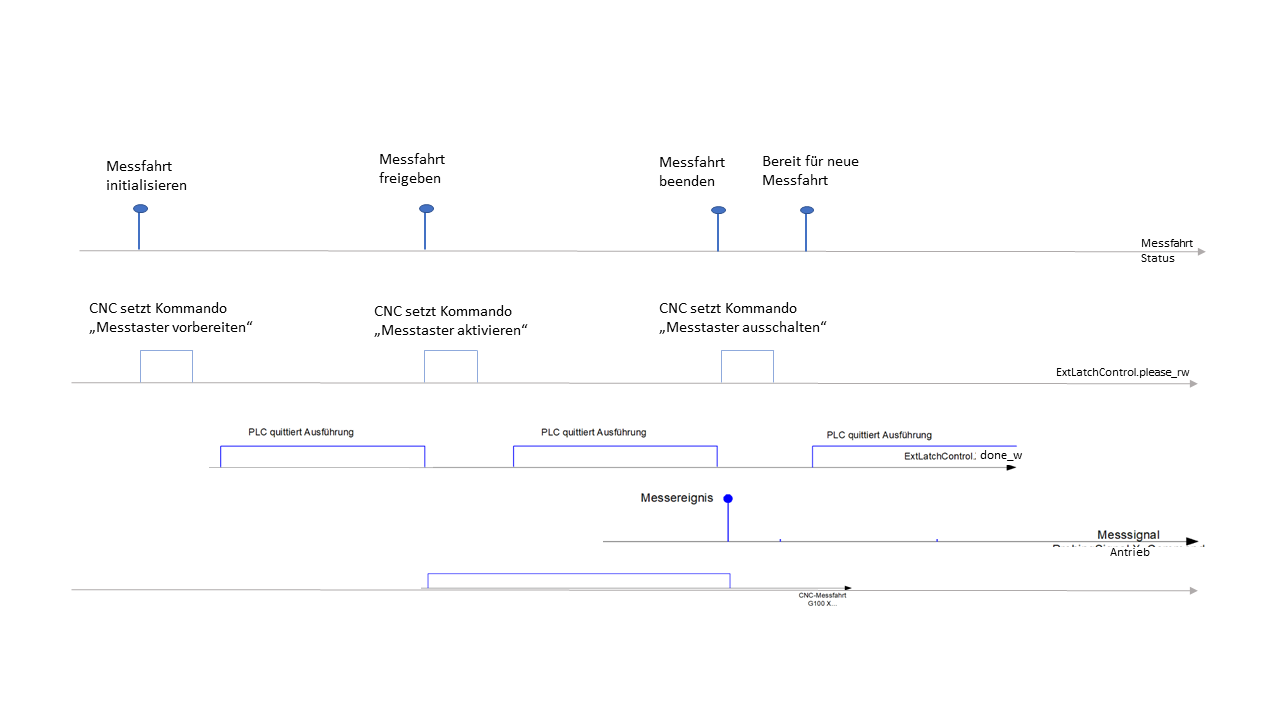

Signal profile with EXT_PROBE_WITH_DRIVE

The block diagram below shows an example of a measurement process using switchable external hardware:

Notice

When the external measuring interface is used, the probing signal of the probing_signal control unit is not dependent on the relevant measurement edge P-AXIS-00518. A positive edge always signals the successful detection of a measured value in the external measuring hardware.

Notice

If the control unit probing_position is not enabled when the measurement event occurs, the CNC uses the actual position of the axis as measurement value at the time stamp of the probing signal occurrence.