3DLight_OnSite | 2022 - 2025

CO2-reduced lightweight construction by 3D printing of structural concrete walls using mobile construction site robots

The aim of 3DLight_OnSite is to achieve significant CO2 savings in the construction industry by developing a continuous CO2-optimized, digitized and automated workflow for the production of multifunctional lightweight components.

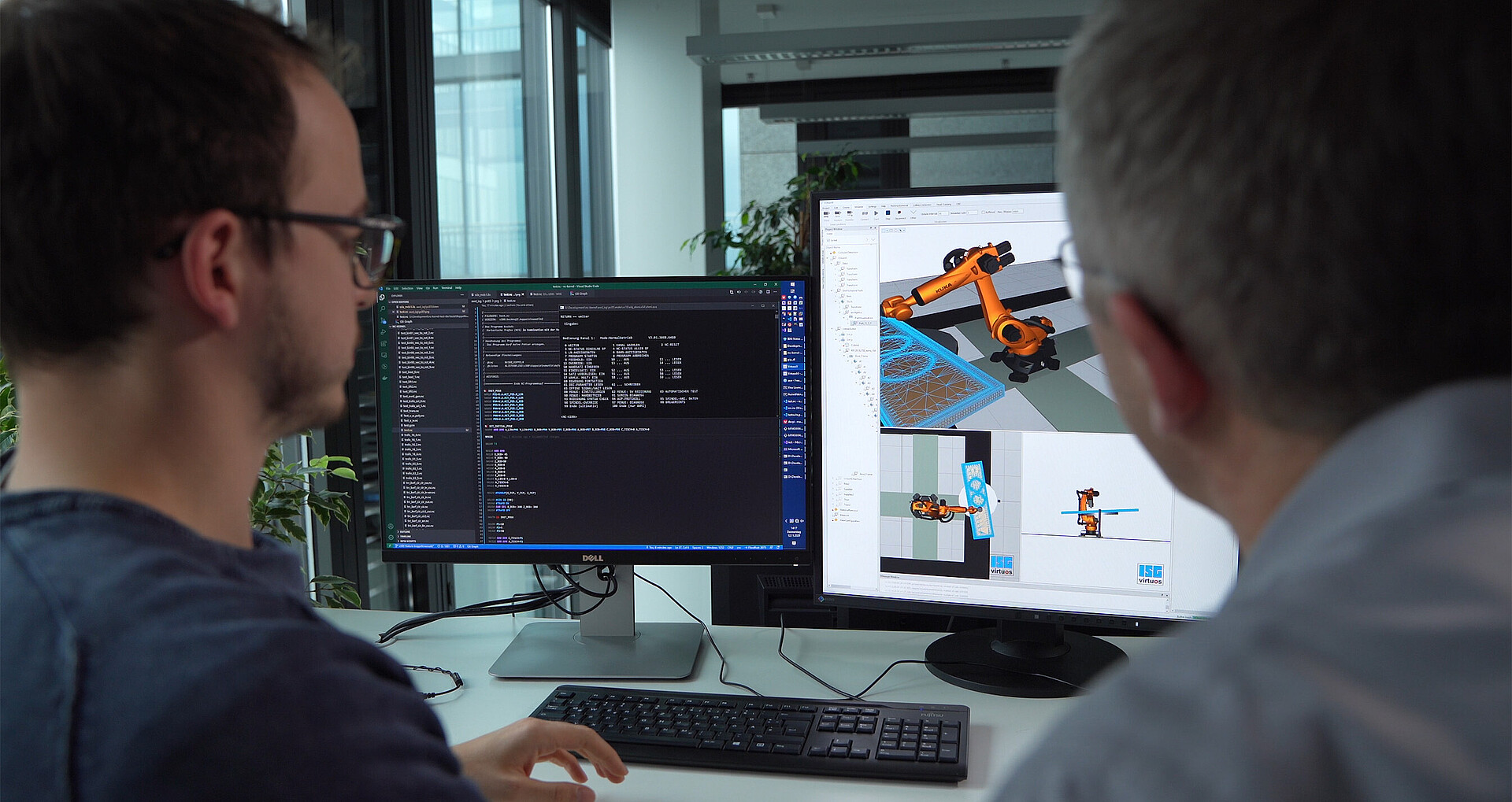

The main innovation lies in the conception, development and testing of in-situ manufacturing in the field of additive manufacturing. Materials and digital planning methods for individualized, multifunctional lightweight concrete components are to be developed in order to manufacture them robotically using additive manufacturing. The results are to be applied in construction operations and used, among other things, for housing construction.

The project is funded by the German Federal Ministry of Economics and Technology based on a resolution of the German Bundestag.

Project partner:

| Ed Züblin AG | Technische Universität Berlin | Hochschule Bochum | Kadia Produktion GmbH +Co |