Vibration Guard mode

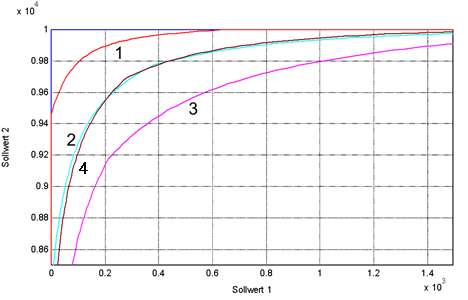

The smoothing curve and therefore the vibration-preventing effect are dependent on parameters and the Vibration Guard mode selected. Each mode has its own characteristic curve and effect.

The following modes are available when using Vibration Guard:

Modes 1 - 3

- Asymmetrical modes (contours may have different forward and backward motions).

- The higher the mode (1- 3), the more sensitive vibration attenuation is compared to deviations to the set frequency (compared to the actual natural frequency of the machine). The Figure - Sensitivity ranges depicts the ranges within which the normalised frequency may lie in order to remain below 5% residual vibration (at damping = 0.1).

- The higher the mode (1- 3), the greater the axis error (or contour deviation) – see Figure - Comparison of Vibration Guard modes

Mode 4:

- Symmetrical mode (contours are identical in forward and backward motion).

The figure above results in the following standard values for each of the modes regarding acceptable percentage deviations to obtain residual vibrations of below 5%:

Table of standard values for sensitivity

Permitted deviations for max. 5% residual vibration (at damping=0.1) | max. negative deviation | max. positive deviation |

Mode 1: | -3% | +3% |

Mode 2: | -13% | +19% |

Mode 3: | -20% | +33% |

Mode 4: | -10% | +13% |

Standard values for permitted percentage deviations between the frequency setting and the real frequency to obtain a residual vibration of below 5% (at damping= 0.1).

1 | Vibration Guard Mode 1 | 2 | Vibration Guard Mode 2 |

3 | Vibration Guard Mode 3 | 4 | Vibration Guard Mode 4 |

Example

Selecting the right Vibration Mode for an axis

Basic procedure:

- Measurements of machine frequencies at three points

- Calculation of percentage deviations

- Assessment of calculation results based on the above Table of standard value for sensitivity

- Measurements of machine frequencies at three points:

- At minimum position of Z axis (6.9 Hz)

- At centre of workspace of Z axis (6 Hz)

- At maximum position of Z axis (5.4 Hz)

- Calculation of percentage deviations:

- minimum Z position at centre of workspace

6.9/6.0 results in 1.15, i.e. +15% deviation. - maximum Z position at centre of workspace

5.4/6.0 results in 0.9, i.e. -10% deviation.

Evaluation of results:

The deviations exceed the permitted range of Mode 1 (+/-3%) but are within of the permitted range of Mode 2 (-13%, +19%). The positive deviation for Mode 4 of +15% is greater than the permitted +13%.

So, in this example, Vibration Guard Mode 2 should be set to a frequency of 6 Hz.

A suitable programming command would then be: #VIB GUARD [FREQ=6 MODE=2]