Aligning the axis systems

- Clamp centre point into spindle chuck.

- B axis zero point: Use a protractor or a try-square to align the rotatory axis B in the tool so that the centre point is oriented perpendicular to the turntable face of C.

- Zero point of X and Y axes: Position X and Y so that the centre point (clamped into the spindle) is flush with the rotary axis of C.

- Z axis zero point: The zero point of the Z axis cannot be approached. This transpires whenever the rotary axis of the B axis lies on the C axis. Place the centre point on the turntable via positioning of Z. Determine the offset from the turntable surface C up to the centre or the B axis. Subtract this offset from the current position→ results in the zero position in the current coordinate system.

- C axis zero point: This can be selected freely depending on the later turntable support with workpiece fastening (see turntable coordinate system). The easiest thing is to position fastening holes in the C axis to a flush position with the direction of the X or Y machine axes.

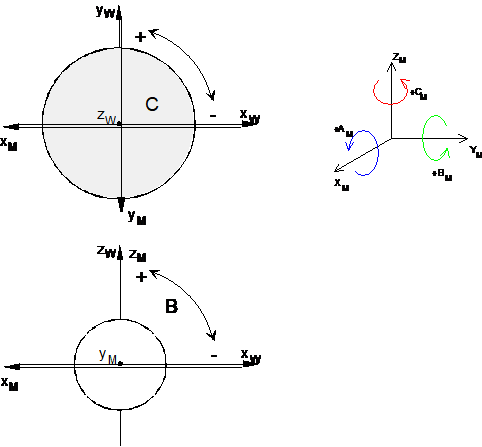

- Figure 2 shows the resulting positive motion direction of the translatory machine axes and the rotation direction of the rotatory machine axes. Note that the machine can also be moved correctly in the conventional 2.5 D mode. For example, the turntable with the workpiece moves to the left when X100 is programmed!

Kinematic ID | Axis sequence | |

1 | X, Y, Z, B, C | |

| ||

Offset parameters | List parameters | Meaning |

HD1 | kinematik[1].param[0] | z axis offset zero point until rotation point B axis |

Axis configuration and kinematic offsets

Excerpt from the channel parameter list:

# Define axis configuration

# =================================

gruppe[0].achse[0].log_achs_nr 1

gruppe[0].achse[0].bezeichnung X

#

gruppe[0].achse[1].log_achs_nr 2

gruppe[0].achse[1].bezeichnung Y

#

gruppe[0].achse[2].log_achs_nr 3

gruppe[0].achse[2].bezeichnung Z

#

gruppe[0].achse[3].log_achs_nr 4

gruppe[0].achse[3].bezeichnung B

#

gruppe[0].achse[4].log_achs_nr 5

gruppe[0].achse[4].bezeichnung C

#

# Define kinematic parameters

# =================================

kinematik_id 1 ( Define the default ID

# Offsets in 0.1 μm

trafo[0].id 1 ( Type 1 for 5-axis kinematic P-CHAN-00262

trafo[0].param[0] 1450000 (Tool clamping point offset up to rotation point B axis

trafo[0].param[1] 0

trafo[0].param[2] 0

trafo[0].param[3] 0

trafo[0].param[4] 0

trafo[0].param[5] 0

trafo[0].param[6] 0

…

Notice

It is essential to specify the value of P-CHAN-00262.

If this parameter is not set, when the transformation is selected with

#TRAFO ON, error ID 21630 is output.