Description

Measuring with G100, G310

When measurement is executed using the NC command G100/G310, an axis position is saved (latched) after a measurement event occurs and the measuring travel may then be terminated.

By default the current position is latched in the drive hardware; alternatively the state of the measuring probe can be transferred to the CNC over the PLC interface. See [HLI//Control commands of an axis].

The measured results can be queried or included in the calculation in the NC program by means of appropriate variables.

The measurement movement may not be smoothed. If polynomial smoothing is selected, it must be deactivated before the measurement block G100.

Measuring with independent axes

When measurement types 1, 2 or 7 are used, a measurement run can also be executed with independent axes (see [PROG//Independent axes]). The measuring point is latched for each axis involved.

An independent measurement run is also possible in parallel to a path motion of a G100 measurement run.

Programing Example

Measurement with G100

%Meas_run

N10 G00 X0 Y0 Z0

N20 X5

N30 G100 X10 Y10 F500

N40 G01 X7

N50 M30

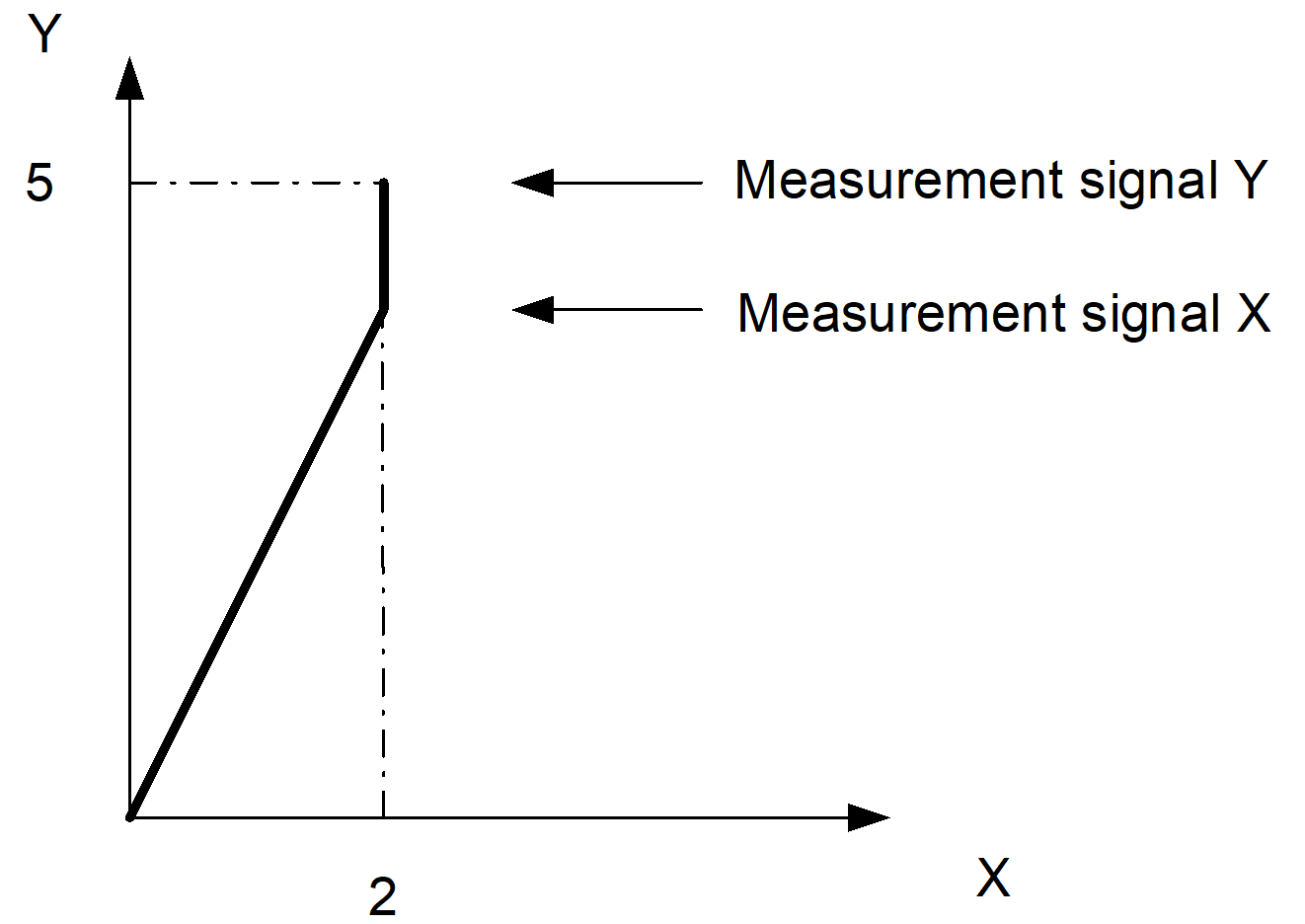

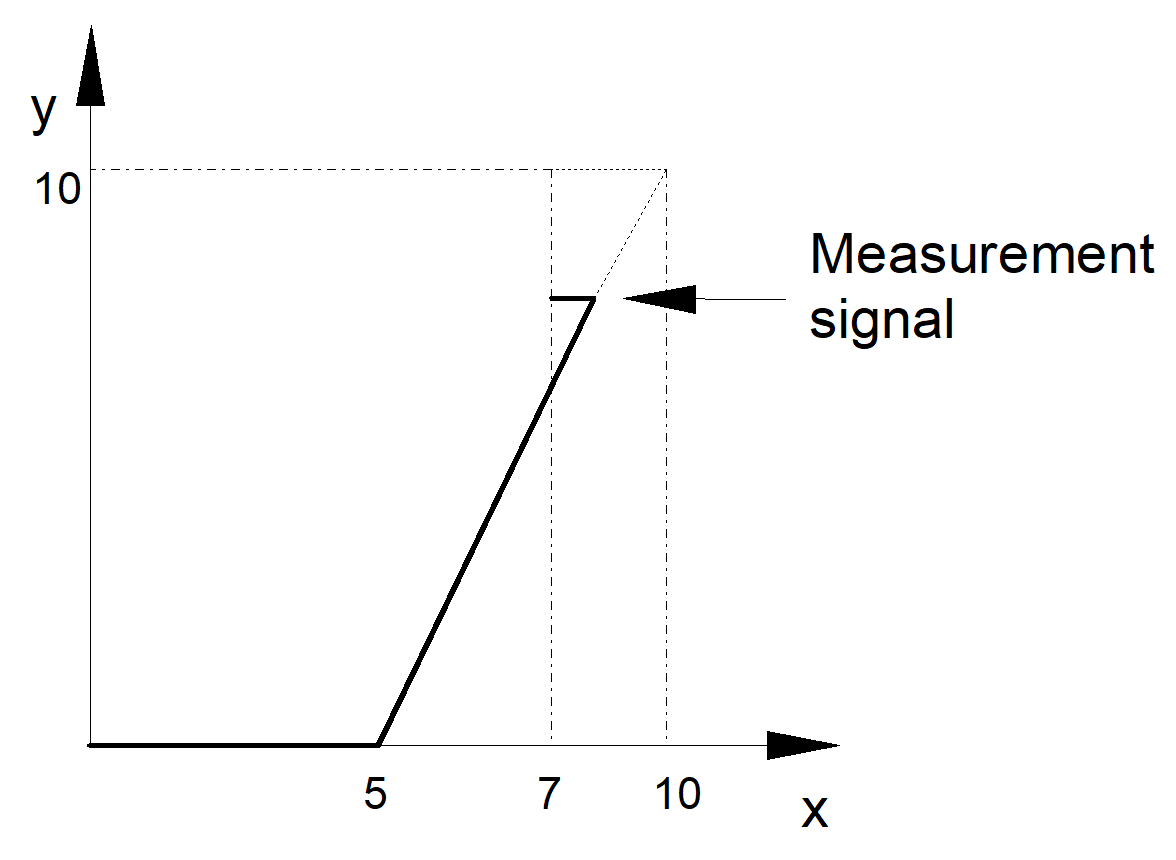

The figure shows a representation of the resulting path:

%Independent_measurement_path

N10 G0 X0 Y0

N20 X[INDP_SYN G100 G90 POS100 FEED500] \

Y[INDP_SYN G100 G90 POS100 FEED1000]

N30 M30