Description

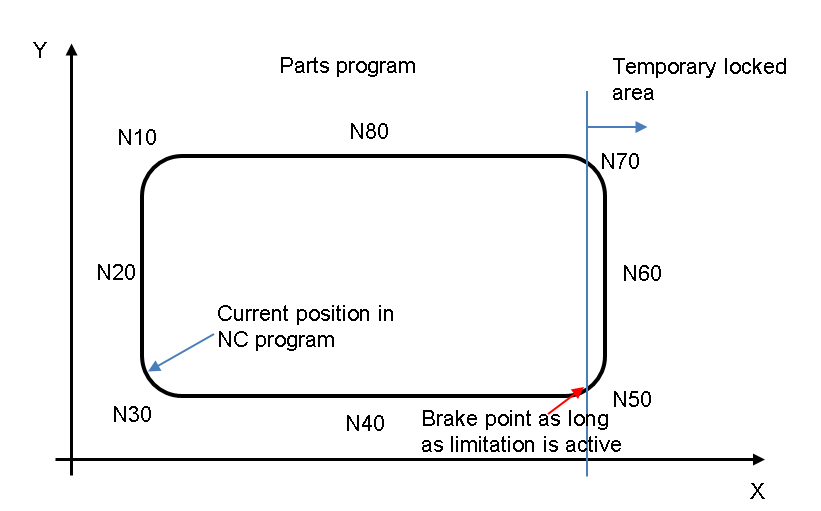

The CNC has the option of prechecking axis positions in the downstream active program. When axis limit violations are detected, machining can then be stopped by feedhold at the zone limit.

The function can also be regarded as a zone-specific feedhold. It prevents all entry to the blocked zone.

- If the current position at the time of zone activation is located within the blocked zone, the machine is stopped immediately. Deceleration takes place at the rate of feedhold acceleration.

- If the current position at the time of zone activation is located outside the blocked zone, the currently active acceleration is effective up to the braking point. The braking point is then located on the zone limit +/- 1 cycle.

The figure below illustrates the possible application:

The limitation of the axis position zone is executed by the PLC. The following options are available:

- Control Units dyn_pos_limit_low/ dyn_pos_limit_high

- Blocks of PLCopen Part 1: MCV_DynPosLimitLow/ MCV_DynPosLimitHigh

The machining program is continued after the PLC cancels the limit.

Activation

The function must be activated by P-STUP-00070.

configuration.channel[0].interpolator.function FCT_LOOK_AHEAD_STANDARD | FCT_DYN_POS_LIMIT

Attention

This function may not be used to implement safety-related functions.

The function is designed to limit the axis position if

- unforeseeable or unplannable events occur during program flow, e.g. caused by a sensor, or

- the restriction is of limited duration.

Supported CNC functions

The function is combinable with the following CNC functions:

- Zero offsets, #ROTATION, #CS

- All slope types: #SLOPE[ ]

- Transformations: #TRAFO[ ]

- Contour smoothing: #CONTOUR MODE, #HSC, #SPLINE

Process limitations

The deceleration ramp is calculated in each cycle in order to stop accordingly. Based on the resulting deceleration duration, 20 random points on this deceleration ramp are checked for limit violation.

In worst-case scenarios, e.g. a long deceleration distance and a very small contour element, it may mean that violations within the blocked area are overlooked.

This occurs in particular when a limit is changed while the program is running.

The following functions are not supported. Axis positions are not correctly monitored for the axes affected.

- Axis polynomial X[POLY L=… A0=…]

- Automatic tracking of the C axis (#CAXTRACK)

- manual mode