Settings of position scaling

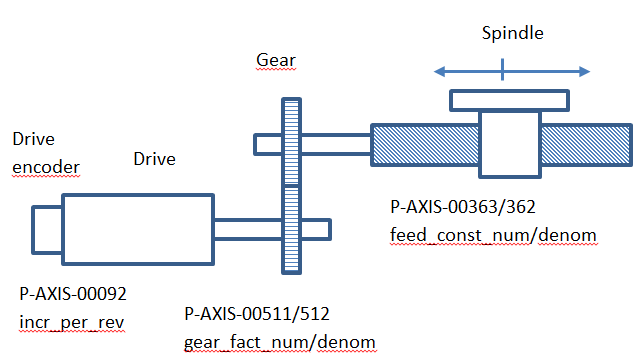

Example 1

Linear axis with a rotary encoder fitted to the motor with 2^20 increments per motor revolution (indirect measuring system), a gear with a gear ratio of 2:1 (input/output) and a ball screw spindle with a spindle pitch of 20 mm.

P-AXIS-00092 | 1048576 | ( incr_per_rev 2 ^ 20 | |

P-AXIS-00362 | 200000 | ( feed_const_num 20 mm | |

P-AXIS-00363 | 1 | ( feed_const_denom 1 revolution | |

P-AXIS-00511 | 2 | ( gear_fact_num gear | |

P-AXIS-00512 | 1 | ( gear_fact_denom gear |

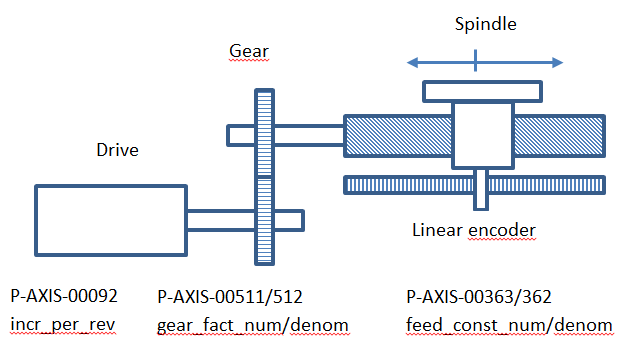

Example 2

Linear axis with a linear encoder fitted to the spindle nut with a resolution of 1 µm (direct measuring system), a gear with a gear ratio of 2:1 (input/output) and a ball screw spindle with a spindle pitch of 20 mm.

P-AXIS-00092 | 1000 | ( incr_per_rev | |

P-AXIS-00362 | 10000 | ( feed_const_num 20 mm | |

P-AXIS-00363 | 1 | ( feed_const_denom 1 revolution | |

P-AXIS-00511 | 2 | ( gear_fact_num gear | |

P-AXIS-00512 | 1 | ( gear_fact_denom gear |

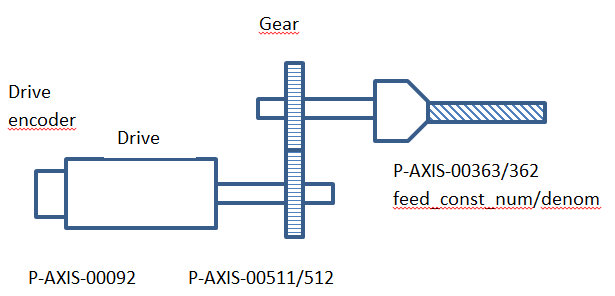

Example 3

Spindle with an encoder fitted to the motor with 2^24 increments per revolution and a gear with a gear ratio of 1:3 (input/output).

P-AXIS-00092 | 16777216 | ( incr_per_rev | |

P-AXIS-00362 | 3600000 | ( feed_const_num 1 revolution | |

P-AXIS-00363 | 1 | ( feed_const_denom 1 revolution | |

P-AXIS-00511 | 1 | ( gear_fact_num gear | |

P-AXIS-00512 | 3 | ( gear_fact_denom gear |

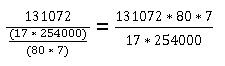

Example 4:

Gear ratios with numerical values with several decimal points.

Assuming:

- A motor delivers 131072 increments per revolution.

- A spindle with a pitch of 1.7/8 inch and

a gear with a ratio of 7:1 are fitted. - Notice that, after ‘expansion’, the product is less than 2^31 - 1. A factor of 1000000 would therefore be too large.

Covered path per motor revolution in 0.1 um:

1.7/8 *25.4 /7 * 10000 = 7710.714285714285714

Expand the above fraction by 10 to remove the decimal point.

(17 * 254000)/(80 * 7)

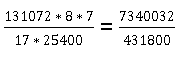

The entire fraction feed_const_num/ feed_const_denom is thus

Shortened by 10:

P-AXIS-00092 | 131072 | ( incr_per_rev | |

P-AXIS-00362 | 7340032 | ( feed_const_num 20 mm | |

P-AXIS-00363 | 431800 | ( feed_const_denom 1 revolution | |

P-AXIS-00511 | 7 | ( gear_fact_num gear | |

P-AXIS-00512 | 1 | ( gear_fact_denom gear |