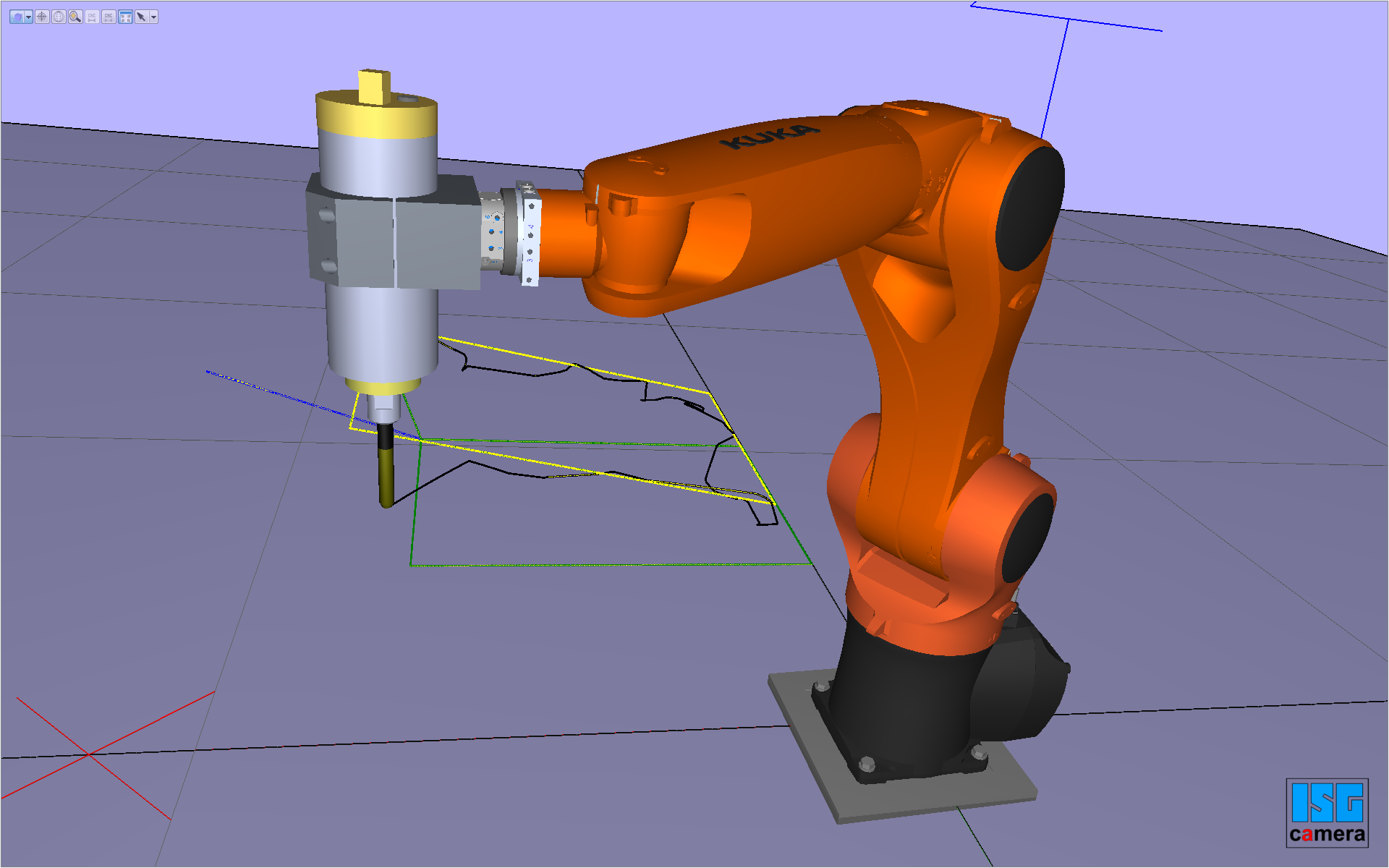

Example 2: Fluctuations in a kinematics base

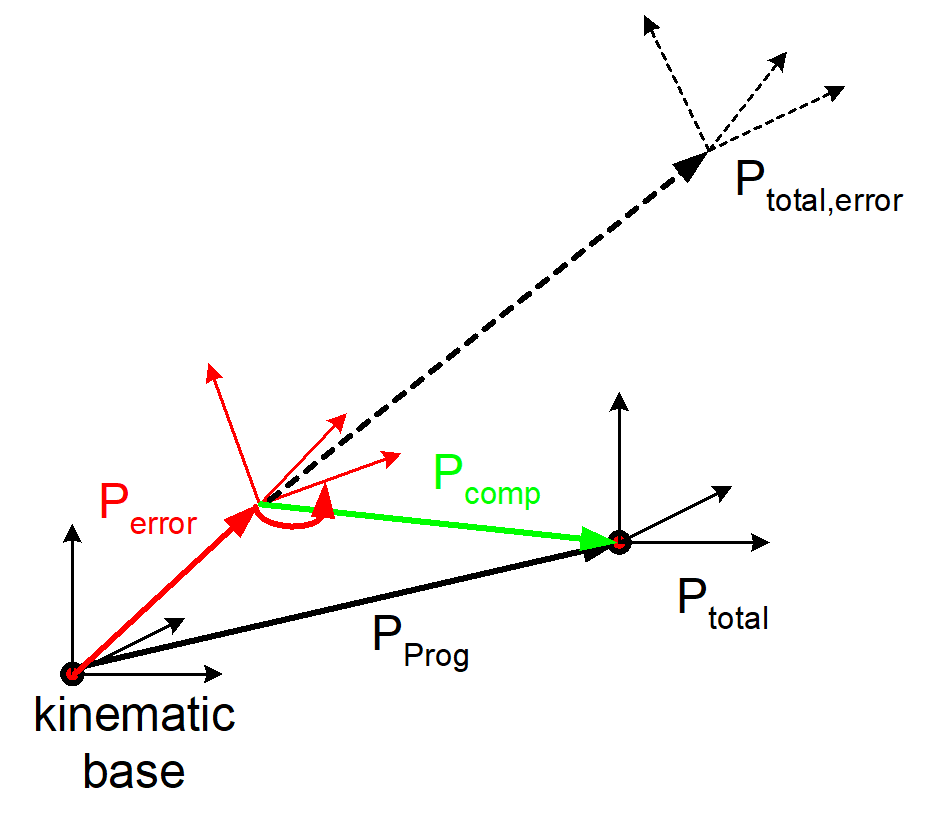

Pure offsets in the base can also be compensated in the PCK tool centre point by an inverse offset. However, if rotations are added, compensation is no longer possible.

The CNC can compensate this by correcting the target position (green). In this case, the programmed target point is approached as if there were no errors in the base.

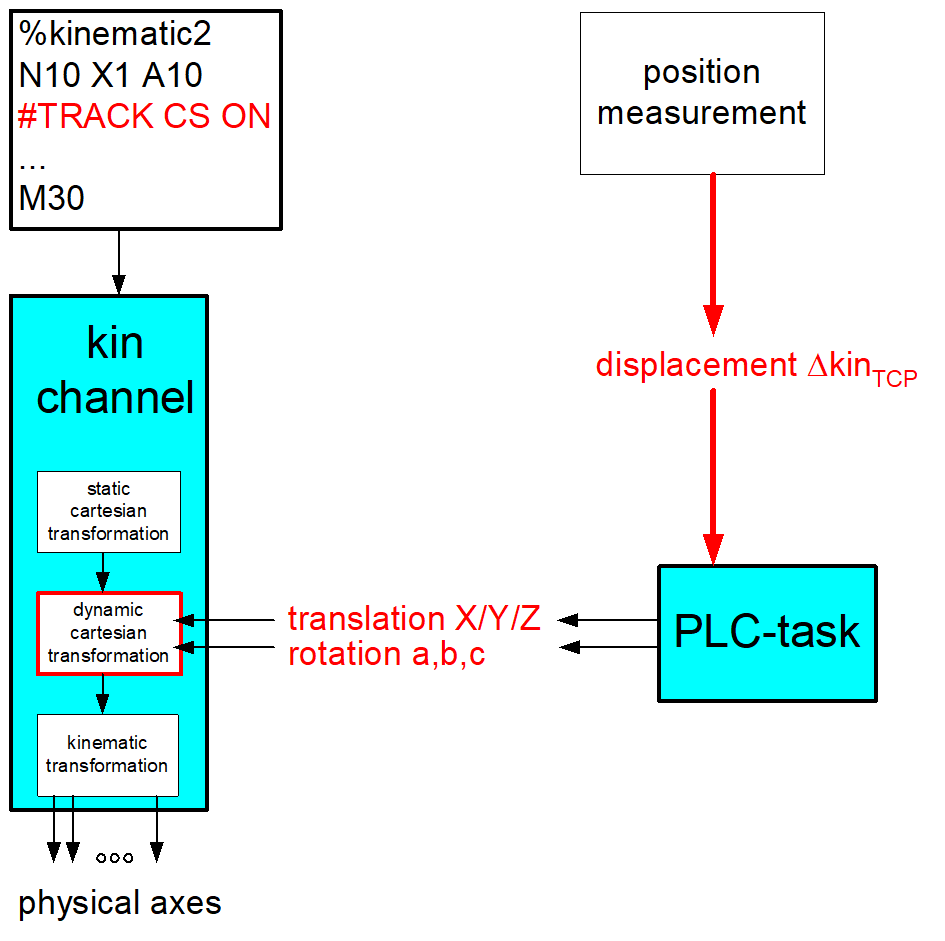

Structure with error compensation

The deviation of a kinematic base is measured. This is then considered by the dynamic coordinate system when the kinematic TCP is positioned to compensate for errors.

Programing Example

Fluctuations in a kinematics base

%dynCS-agilus

…

;Move to safe position to deselect compensation

N1000 Z200

;Compensate for error in base; error compensation by PLC

N1010 #TRACK CS ON [ID=0 KIN_BASE OPTION=0 FILTER=1000]

N2000 Z100

;Move with error compensation

N2010 G01 X100 F100

…

;Move to safe position to deselect compensation

N9000 Z200

N9010 #TRACK CS OFF [WAIT]

;Move without error compensation

N2000 G01 X100 F100

…

M30