Restart to the contour after block search

Move back to command position

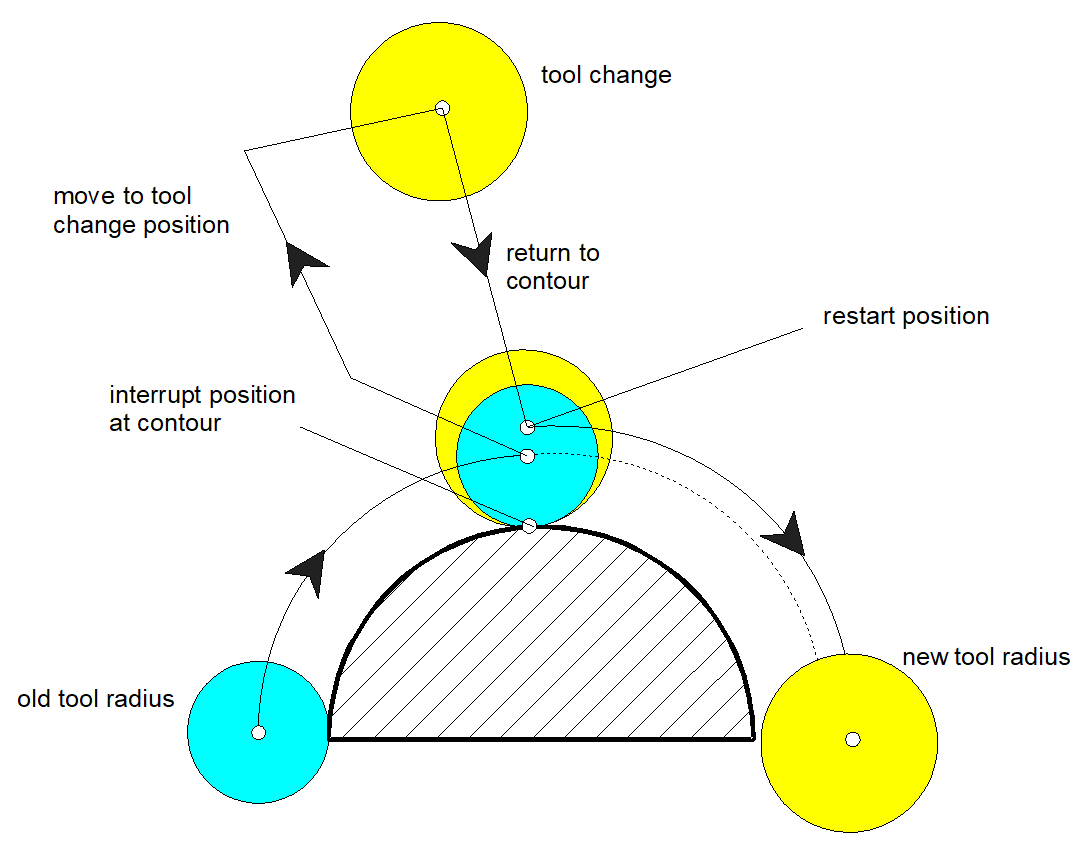

Before normal machining can be resumed, the axes must be located back at the command positions of the NC program (restart to the contour).

This starting movement is executed either

- by an NC program specified by the operator or

- manually before start of block search or

- automatically in a straight line at the end of block search.

As the above figure shows, the covered distance in the current block must be specified in per thousand relative to the entire block length since the absolute block lengths are different for circular blocks with different tool radii after block search.

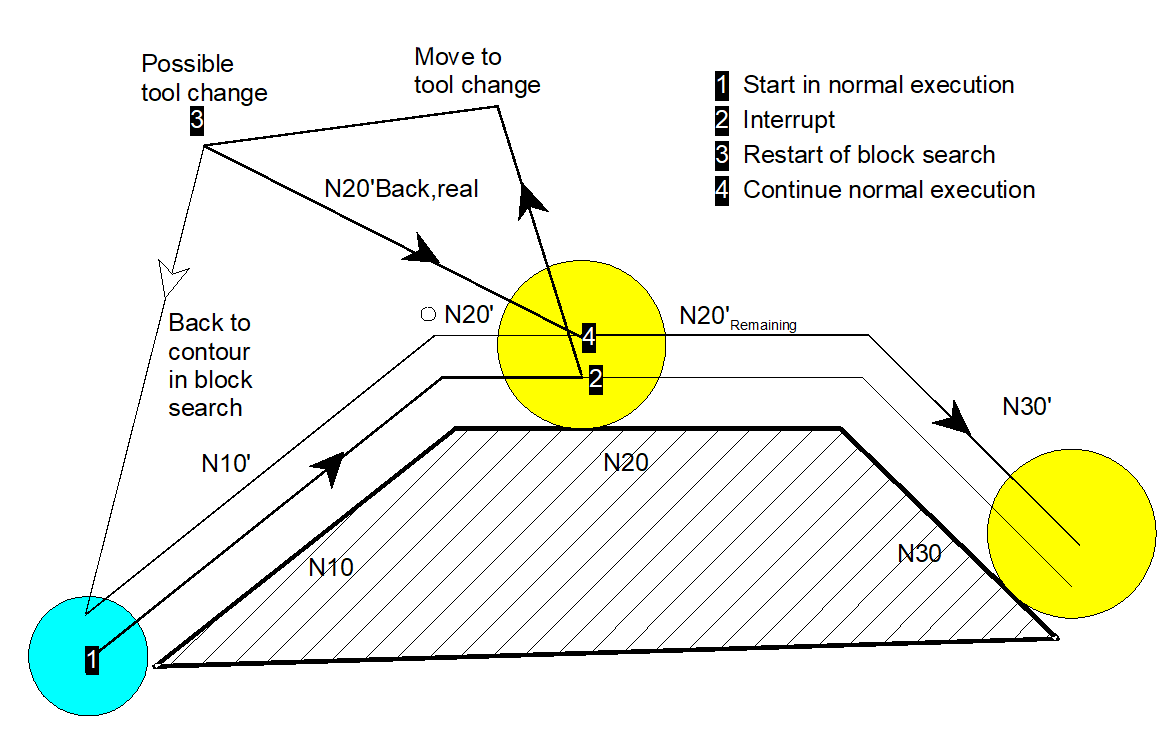

Automatic restart to the contour

The automatically generated motion is moved in rapid traverse (G00).

Example

- Operator starts normal program at position 1.

- Program interrupt at position 2 in block N20.

- Axis is moved to position 3 and the tool may be replaced (tool radius may change).

- The program context is restored at the end of block search to movement to position 4. Automatic restart occurs in a straight line.

- The program can be continued with the new tool radius in block N20.

Parameterisation

Automatic restart = TRUE

mc_cmd_bs_auto_return_w

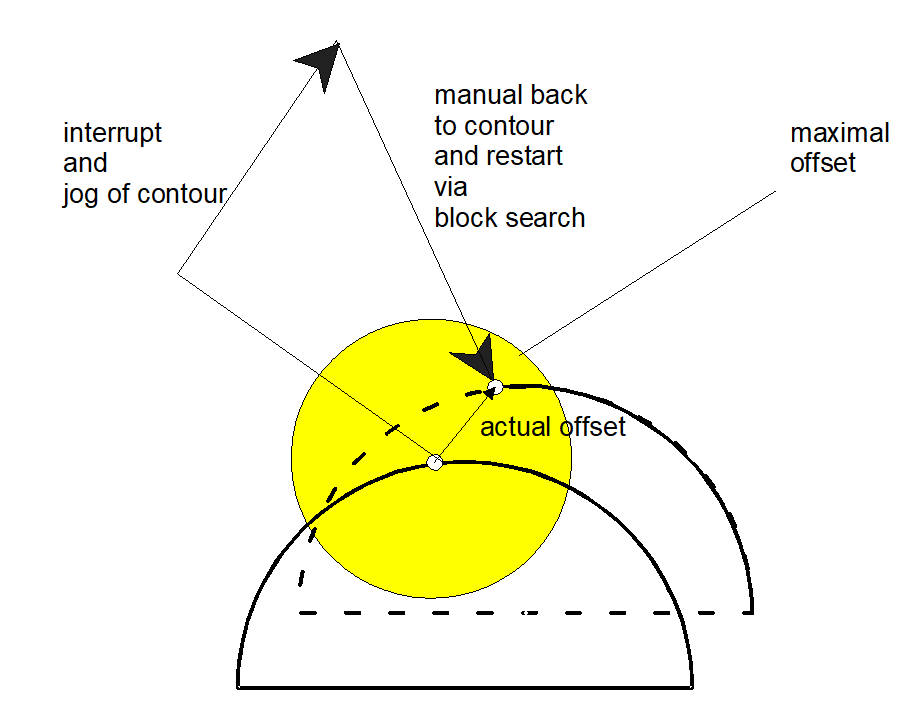

Manual restart to the contour

If restart to the contour is executed manually and the axes are not repositioned exactly on the contour, an offset occurs between the command positions of the NC program and the actual positions. Here, the operator can specify the maximum permitted three-dimensional offset.

Parameterisation

Maximum permitted offset after block search between command position and actual position

mc_cmd_bs_deviation_max_w

Notice

Backward motion is not possible with an offset > 0.

Notice

If an offset is active, please note the following in connection with software limit switch monitoring or collision monitoring:

The offset between the command positions and the actual position may result in SLS errors or collision errors although the actual positions are still within the valid range and no collision has occurred. Similarly, an SLS overshoot can not be detected in path preparation, only in the position controller. In this case, a collision cannot be detected in path preparation.