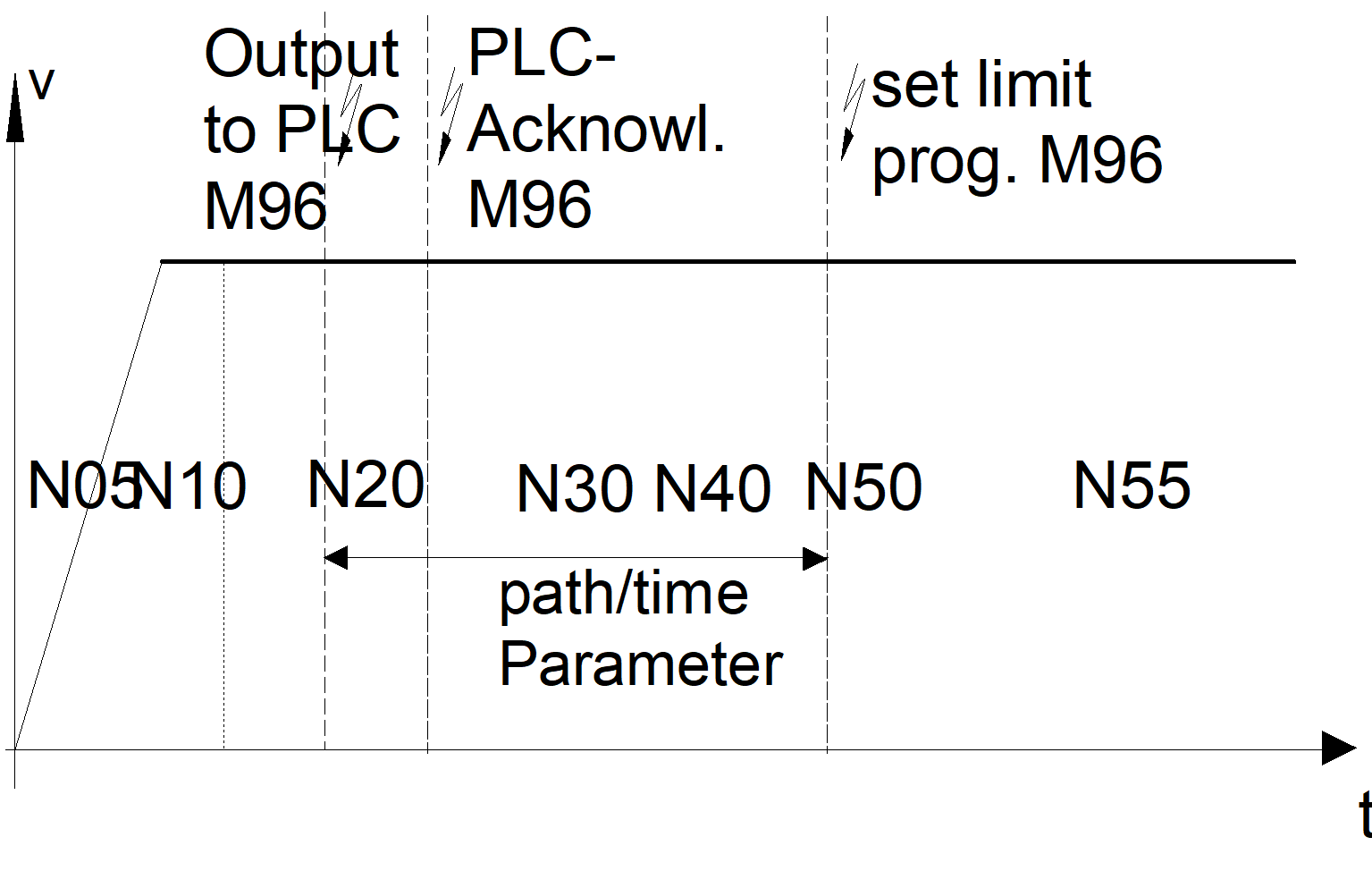

Example with MEP_MOS and MET_MOS

With these M/H functions the CNC calculates the required output time across the default path parameter or time parameter. In this case, look-ahead profile planning takes place internally. The basic calculation model can be modified using P-CHAN-00209.

The parameter P-CHAN-00274 is used to increment the number of blocks for the look-ahead (output position preview).

Pre-output of the M function in accordance with the specified path or time. Without synchronisation, M/H functions must be read by the PLC like all MOS.

Initialising in the channel parameter list

# Definition of M functions and types of synchronisation

# ======================================================

:

m_synch[96] 0x00100000 MEP_MOS

m_synch[97] 0x00200000 MET_MOS

#

# Pre-output time/distance setting with MET_MOS, MEP_MOS

# =======================================================

m_pre_outp[96] 100000 in 0.1 um

m_pre_outp[97] 40000 in us

Programing Example

MEP_MOS and MET_MOS

N10 G01 X10 G90 F5000

N20 X20

N30 X30

N40 X40

N50 M96 (M96 MEP_MOS m_pre_outp = 250000,)

(or MET_MOS m_pre_outp = 300000us)

N55 X80

N60 X0

M30