Description

Machine switching functions

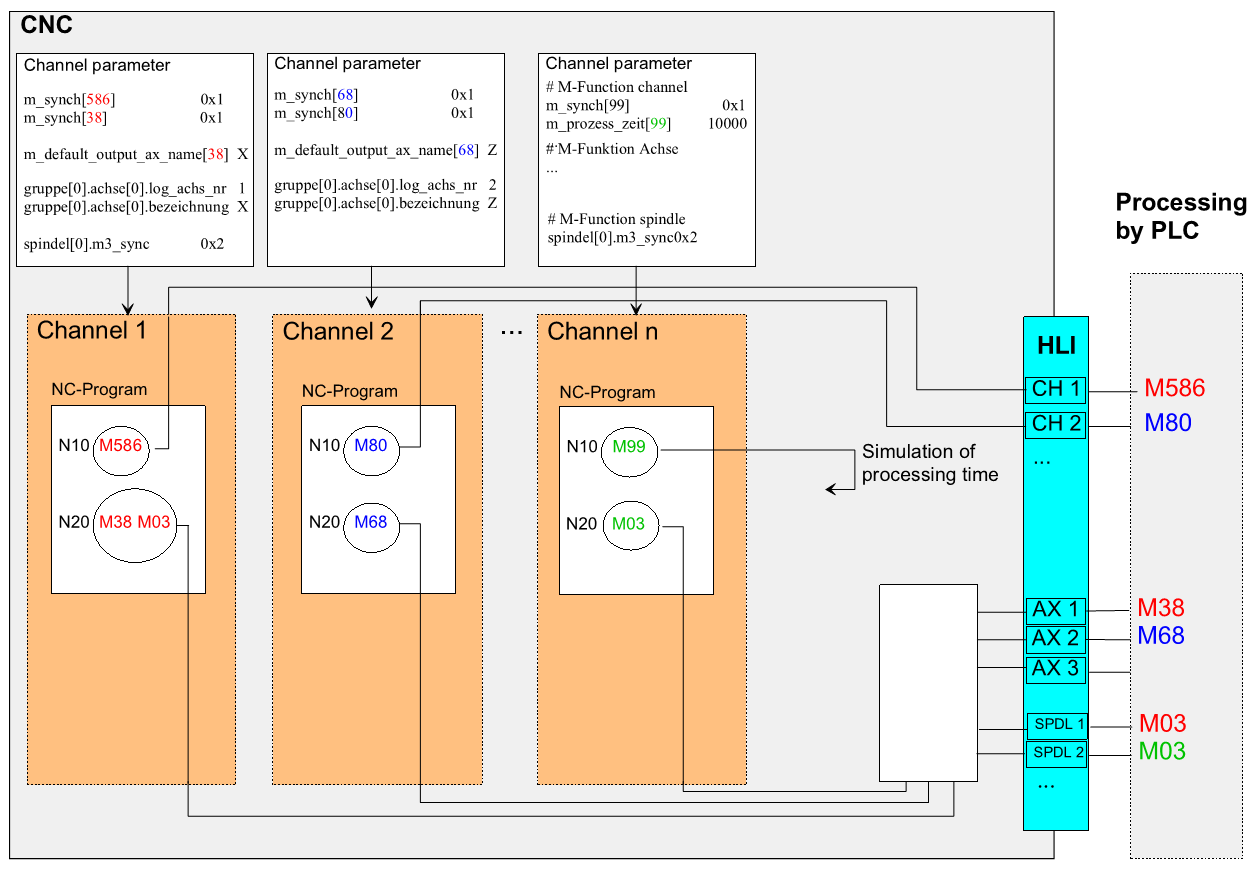

The timing of the output of M and H functions to the PLC and its subsequent reaction can be synchronised in various ways with motions to be executed.

To simulate the machining time of an M or H function, a time period can be specified in order to determine the run-time of a CNC program.

Characteristics of M and H functions

- Possible synchronisation methods

- Freely available or default in compliance with DIN 66025

- Machining time can be determined

- Channel or axis-specific output

- Spindle-specific

The CNC channels are each parameterised via an initialisation list (see Channel parameter list). All M and H functions must be specified here. Instead of a channel-specific assignment, an axis-specific assignment and a synchronisation method can be defined.

At the interface to the PLC (High Level Interface) [HLI], M and H functions are output in the channel and axis-specific areas and the PLC further processes them and confirms them accordingly.

Notice

For safety reasons, M and H functions cannot be used in the CNC program if a synchronisation method is not specified.

In this case, the CNC generates the message P-ERR-20157.

Output

The following options are provided for output to the PLC:

- No output

- Before / after a motion

- After an event

Output to the PLC (HLI) can take place in different ranges of the interface:

- In the channel range

- In the axis range

Synchronisation

The following options are available for synchronisation with a motion to be executed:

- No synchronisation

- Before / after a motion

- Synchronisation at the transition to the next motion block with machining feed rate ('late' synchronisation implicit)

- For an explicit request ('late' synchronisation explicit)

- During a motion block (example: edge banding)