Automatic program commanding as comparison

Automatic program

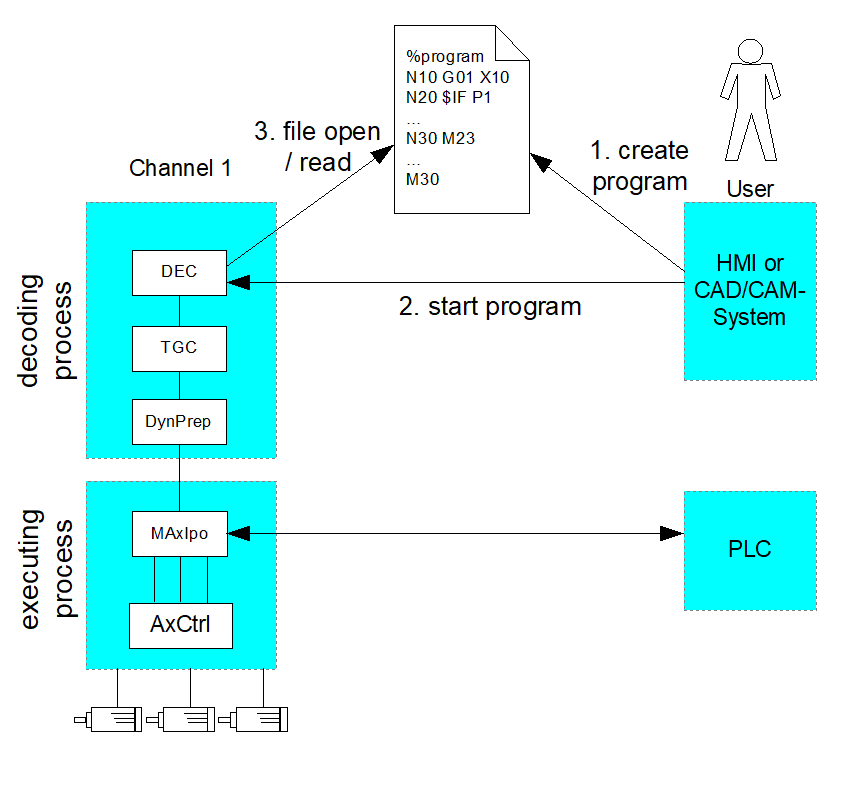

In automatic mode the user generates the program in advance. The basic execution of sequences (geometry) is then defined. After the NC program is started, it may/can no longer be modified.

The process can still be influenced at the time of program decoding by querying variables/parameters over the user interface or the PLC (conditional branches).

At the time of program execution, the axes are moved in accordance with the programmed geometry and information is sent to the PLC or execution is synchronised with the PLC.

The PLC can still influence the process online by using specific NC functions:

- Velocity: feed hold, override, reduced velocity (safety)

- interrupt/resume, abort, move backward

Function/action | Automatic program | Data streaming |

|---|---|---|

Start/initialise NC status data | Each time the program is started, the channel's default settings are restored, i.e. programs do not influence each other globally (exception: modal parameters, etc.). | Only at the start of streaming, i.e. status data of the NC remains valid throughout the duration of streaming |

Response to errors | NC reset with reset of NC status data | NC reset with reset of NC status data An NC reset without reset of the NC is currently not possible. |

Data throughput | Implicit by access to the file system | Provided by filling the data stream "in good time", i.e. axis motion can be interrupted by delaying filling. |

Velocity planning, look ahead (HSC) | Cross-block velocity planning is possible to the full extent | Planning limited, may be only possible for the specified blocks |

Process changes | No longer possible after program start if branches (e.g. via external variables) are not already considered in the program. | Program parts not yet specified can still be modified. |

Jumps/loops | Jumps to program flags possible, higher-level language constructs with loops possible | No return jumps possible, no loop programming possible |

Fast forward | Via block search (jump to block number, block counter, file position) -> system state at forward position is established automatically | By programming system with corresponding omission of forward areas -> system state at forward position must be established manually. |

Backward motion | NC functions, possible at any time by PLC command | Via NC functions or by specifying an inverted data stream |

Automatic geometry changes at the block transitions (phases, radii, smoothing, splines, etc.) | Possible via standard NC functions | By CAD/CAM system, no consideration of several path segments in the NC because execution is always enabled immediately. Without implicit #FLUSH, also possible by NC |

Tool radius compensation | Standard NC function | To be executed by CAD/CAM system Without implicit #FLUSH, also possible by NC |