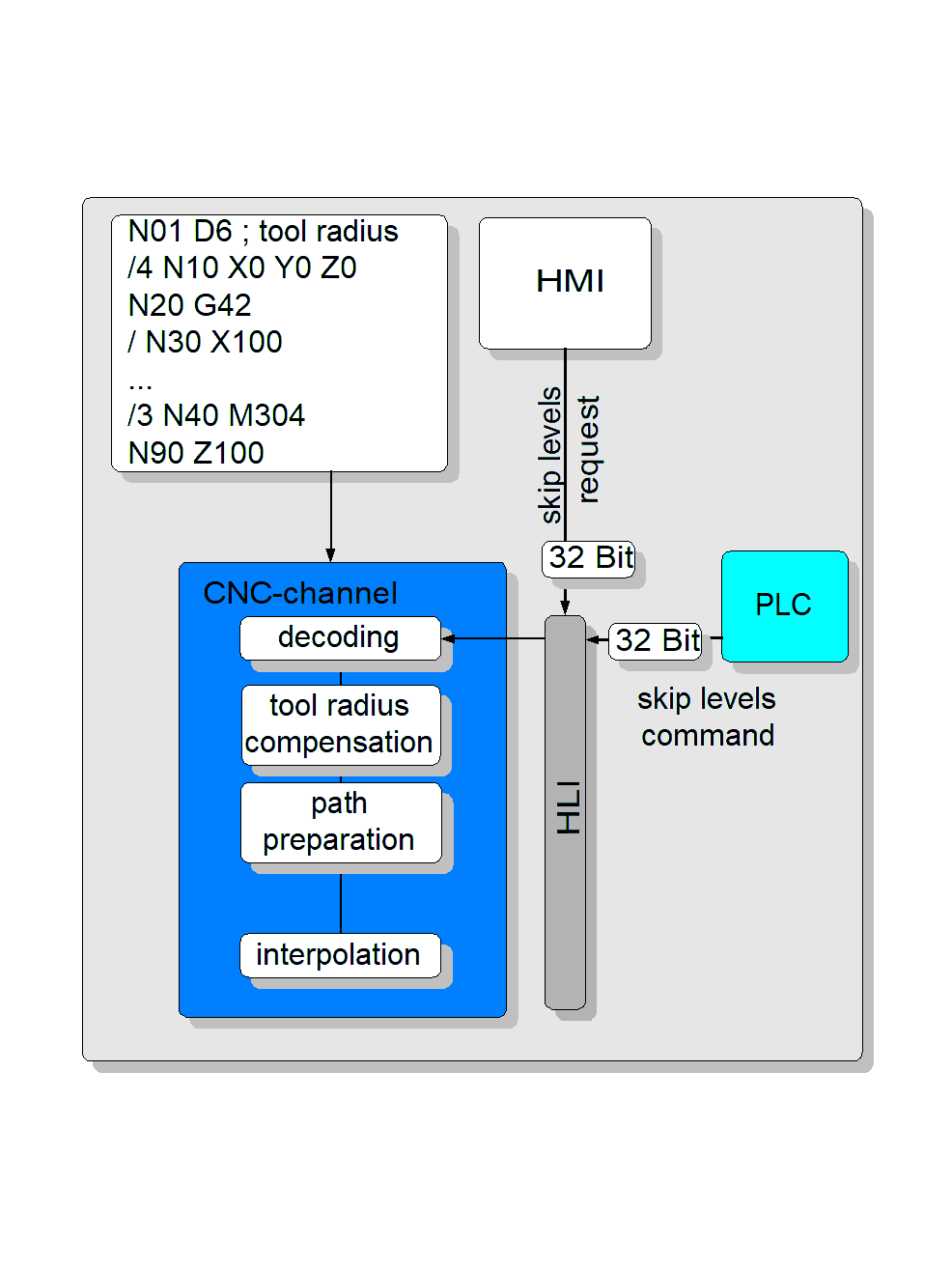

Extended skipping (skip levels)

Release Note

This function is available as from CNC Build V3.01.3021.1 and higher.

Attention

Changing the interface to HMI and PLC

The BOOL interface data type was changed to 32 bits (UNS32) for the skip levels.

You can now use different skip levels in the NC program using this extension. These skip levels can be set either on the operating console (HMI) or in the PLC before main program start.

In the Extended Skipping function, changes in skipping settings take effect immediately while the NC program is active. Defined break points can be implemented, e.g. by M functions followed by #FLUSH WAIT, to ensure that these skipping setting changes are safely accepted and become effective in the NC program.

The syntax programming is a slash "/" followed by a number to define the skip. The maximum number of skip levels is 10. This cannot be parameterised.

Syntax | Skip level | Hex value at interface | Decimal value at interface |

/1 | One | 0x001 | 1 |

/2 | Two | 0x002 | 2 |

/3 | Three | 0x004 | 4 |

/4 | Four | 0x008 | 8 |

/5 | Five | 0x010 | 16 |

/6 | Six | 0x020 | 32 |

/7 | Seven | 0x040 | 64 |

/8 | Eight | 0x080 | 128 |

/9 | Nine | 0x100 | 256 |

/10 | Ten | 0x200 | 512 |

Example:

/5 N100 G00 X150 ;Block is skipped when skip level 5 (0x010) is set.

Skip levels which are active simultaneously are enabled by bitwise ORing.

Example:

Enable all skip levels by setting 0x3FF.

Programing Example

Using skip levels

%skip_levels

N0 G0 X0 Y0 Z0

/1 N10 X1

/2 N20 Y2

/2 N25 Y2.5

/3 N30 Z3

/4 N40 X-1

/4 N45 X-1.5

/ N47 X-1.8 ;Standard skipping

/10 N50 Y-2

/100 N60 Z-30 ;Error 21655

N999 M30

The valid range of skip level values is from 1 to 10. A value programmed outside this range generates error ID 21655.

Notice

For reasons of compatibility, skip levels ‘/’ and ‘/1’ are each addressed by the same bit 0x001 of the HMI/PLC control bit mask. However, the effect of the standard skip level ‘/’ can only be defined before main program start and remains constant until program end. In this case, changes to skip levels while the NC program is active only influence programmed ‘/1’ levels, if any. We recommend not to use ‘/’ and ‘/1’ in the same NC program for reasons of clarity.