Channel synchronisation

When a multi-channel controller is used (particularly in the case of n > 2), situations may occur in which it is absolutely essential to maintain with specific run sequences between channels.

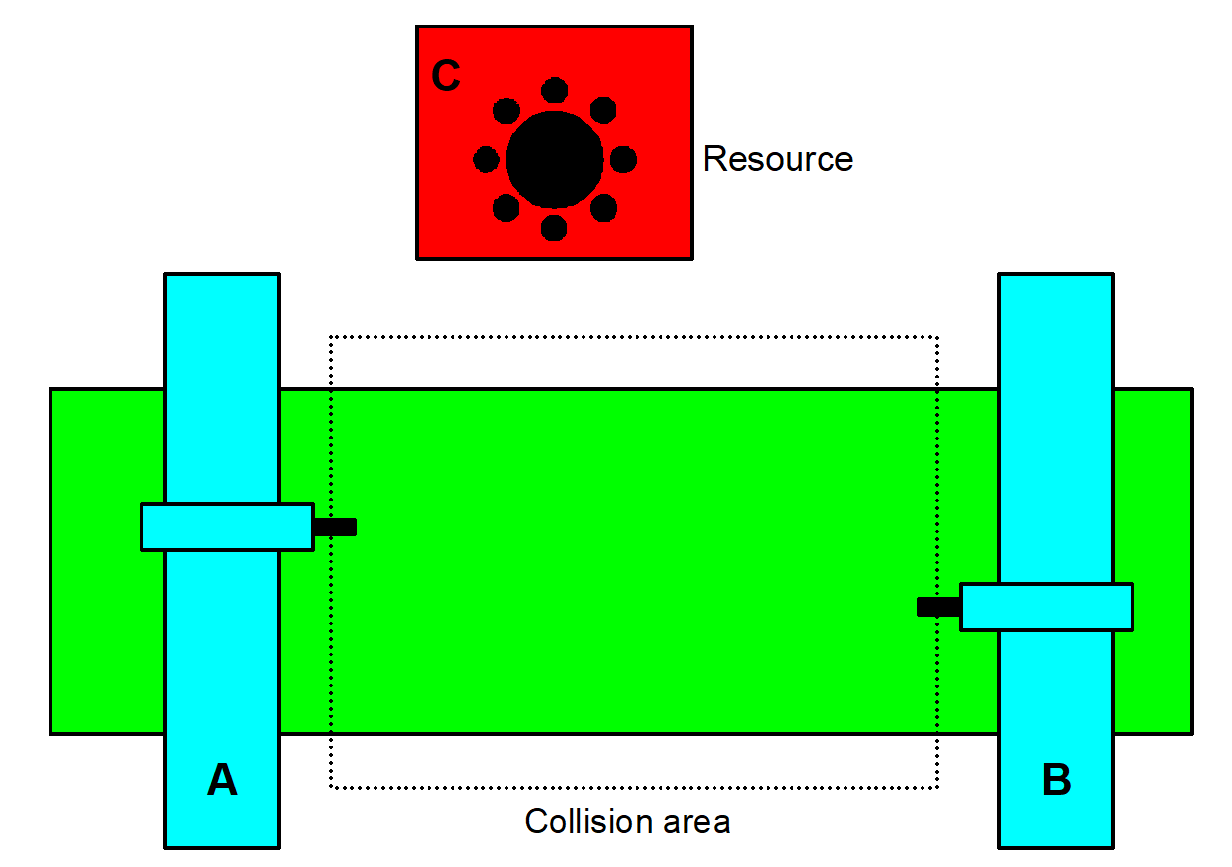

The example in the figure above shows such an application in which two machining units (A and B) share a common machining space. Similarly, both machines use the tool changer resource (C). In order to avoid collisions in such a machine configuration, the NC programs of the various controller channels must be synchronised with each other at specific points. For example, in the above case, column A may not enter the collision space while column B is still located there. Similarly, column B may not use the tool changer if column A is currently accessing it.

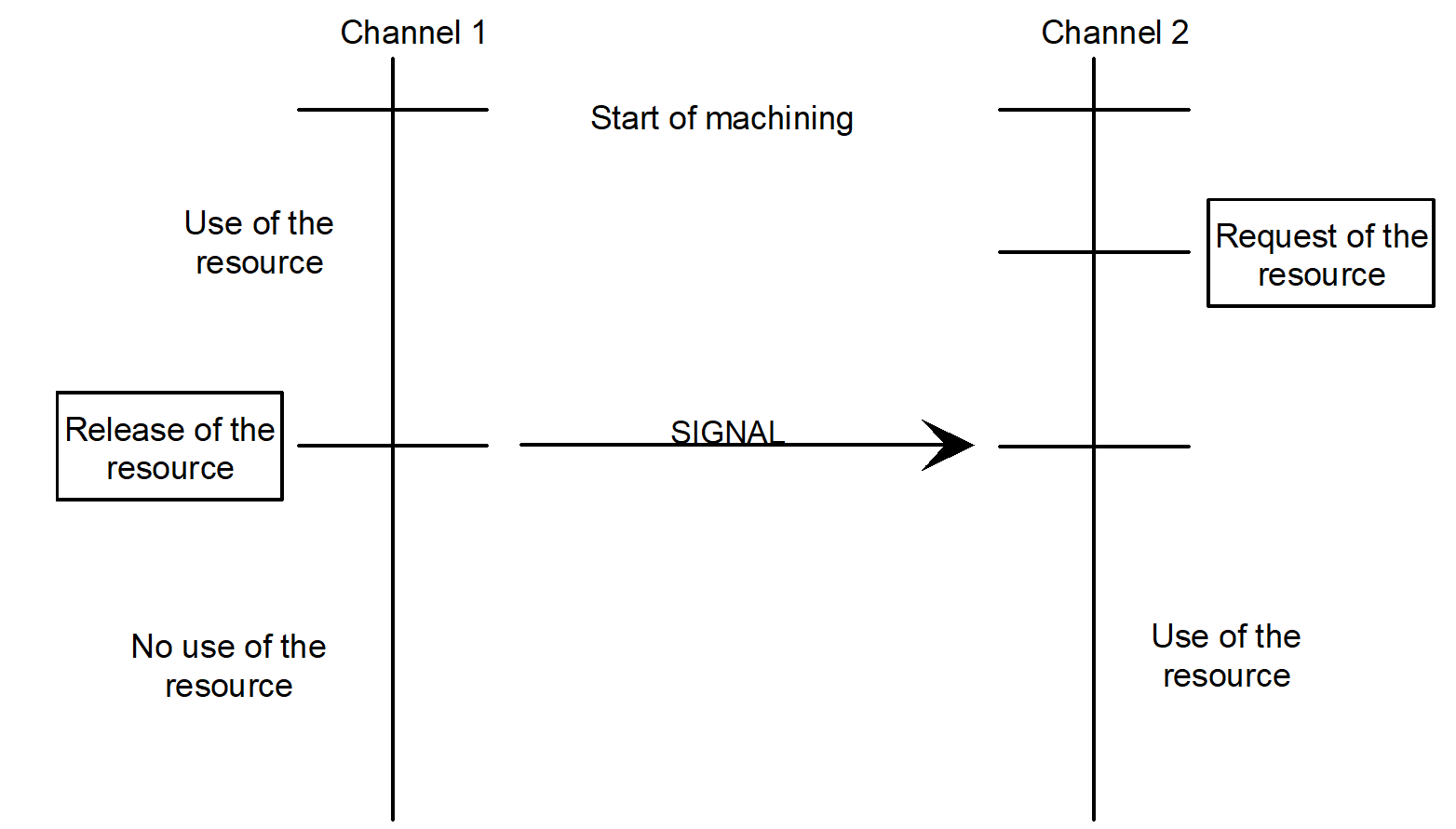

For example, the time sequence in the two channels of the controller as shown in the figure below results from an access to the tool changer resource.

The required synchronisation is based on sending and waiting for signals and is performed by the NC commands in the NC programs described below.

If a large number of signals are sent in one channel and they are processed late in another channel, it may be that there is insufficient memory to store the number of synchronisation events.

As of V3.1.3081.02 or V3.1.3108.02, P-STUP-00119 can be used to define the number of synchronisation events to be stored. Here, each signal or wait command represents an event. If this parameter is not set, 150 events are available by default. In addition, P-STUP-00118 can be used to define whether the decoder waits for an acknowledgement for default signals at decoder level when the signal command is stored. This prevents the limit of the number of synchronisation events from being exceeded.