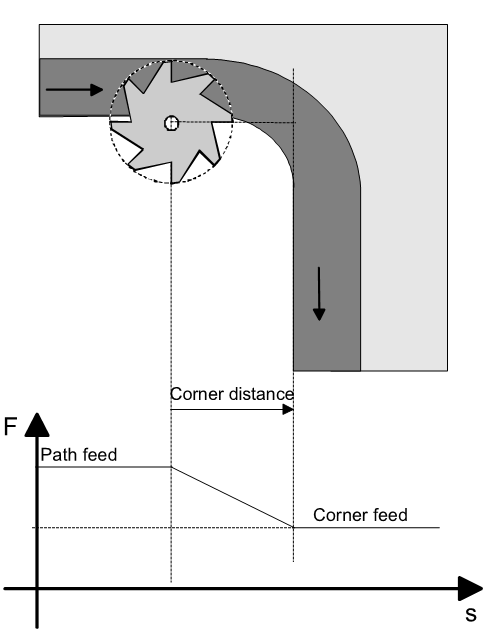

Corner deceleration

In the milling process, the removal volume Vz and the associated spindle performance required in the inside corners increases as a function of block transition geometry since the tool already removes material from the subsequent contour (see figure below).

If machining is always performed at the spindle's performance limit, the feedrate in the corner section must be reduced so that there is also sufficient spindle performance in the inside corners. In order to stay within the spindle’s performance limits, it must be possible in the NC program to define a point on the path after which the velocity can be reduced. There are three NC commands available for this corner deceleration: one for parameterisation, one for activation and one for deactivation.