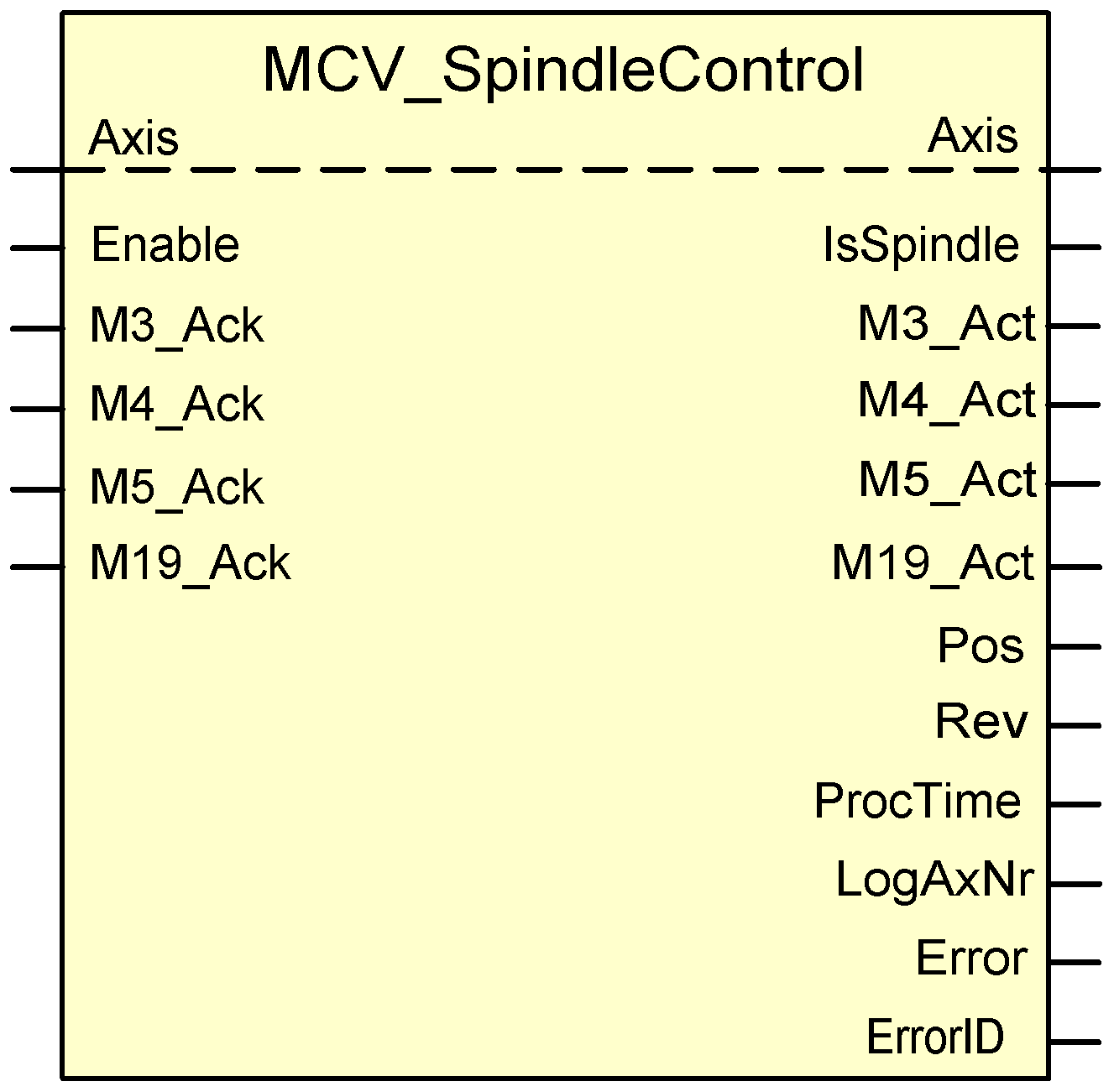

MCV_SpindleControl

The FB supplies to its outputs all the information on technology functions which are of interest to the PLC when a spindle is programmed by NC blocks.

Block diagram

FB parameters

VAR_IN_OUT | ||

Variable name | Data type | Description |

Axis | AXIS_REF | Axis reference of spindles |

VAR_INPUT | ||

Variable name | Data type | Description |

Enable | BOOL |

|

M3_Ack | BOOL | Input to acknowledge an M3 technology function output for a specific spindle. |

M4_Ack | BOOL | Input to acknowledge an M4 technology function output for a specific spindle. |

M5_Ack | BOOL | Input to acknowledge an M5 technology function output for a specific spindle. |

M19_Ack | BOOL | Input to acknowledge an M19 technology function output for a specific spindle. |

VAR_OUTPUT | ||

Variable name | Data type | Description |

IsSpindle | BOOL | TRUE indicates that the axis applied to the axis reference is identified as a spindle in the NC channel. |

M3_Act | BOOL | Becomes TRUE when the NC kernel outputs an M3 technology function for the spindle and remains TRUE until a rising edge is detected at “M3_Ack”. |

M4_Act | BOOL | Becomes TRUE when the NC kernel outputs an M4 technology function for the spindle and remains TRUE until a rising edge is detected at “M4_Ack”. |

M5_Act | BOOL | Becomes TRUE when the NC kernel outputs an M5 technology function for the spindle and remains TRUE until a rising edge is detected at “M5_Ack”. |

M19_Act | BOOL | Becomes TRUE when the NC kernel outputs an M19 technology function for the spindle and remains TRUE until a rising edge is detected at “M19_Ack”. |

Pos | DINT | Commanded spindle position when programming M19 and [Spindelname].POS |

Rev | DINT | Commanded spindle speed when programming [Spindelname]<Drehzahl> |

ProcTime | UDINT |

|

LogAxNr | UINT | Logical axis number of the spindle |

Error | BOOL | Indicates TRUE when an error occurs. |

ErrorID | UDINT | Error code |