Settings for edge machining (edge_machining.*)

Release Note

This functionality is available as of Release V2.11.2009.12. It is enabled in the start-up list ([STUP]) for each CNC channel as follows (as an example):configuration.channel[<i>].path_preparation.function FCT_DEFAULT | FCT_EMF

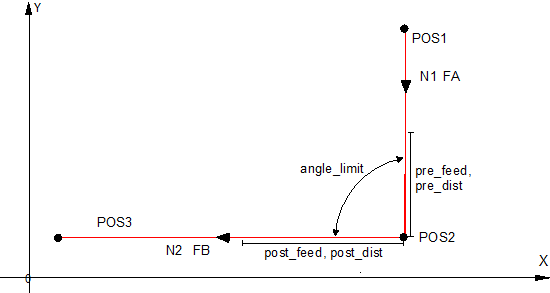

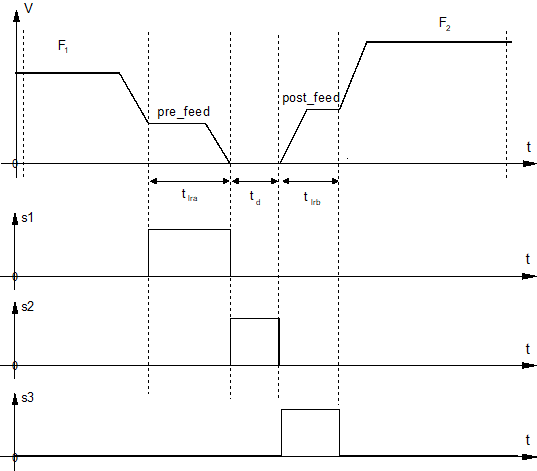

Depending on the machining technology it may be necessary to control the machining process especially on sharp contours (edges). In the case of a sharp edge (defined by the angle difference between two contour elements), the path velocity at the edge is modified depending on pre-defined parameters. In addition, three signals are generated, derived from path velocity. These signals are supplied to the PLC interface (see HLI documentation, Status information of a channel -> Edge functions -> Signal_1, Signal_2, Signal_3). Linear or circular blocks can be programmed as contour elements. No check is made here whether they are inner or outer contours. If the functions ‘Insert chamfers and roundings (G301/G302)’ or tool radius compensation (G41/G42) are active, additional contour elements can be generated. They then result in a different bend angle than exists between the two original contour elements.

The following parameters are required to set the edge machining function:

# Parameterise edge machining function

# ======================================

edge_machining.enable 1

edge_machining.angle_limit 150000 [0.0001°(degrees)]

edge_machining.pre_dist 100000 [0.1µm]

edge_machining.pre_feed 16666 [µm /sec]

edge_machining.wait_time 10000 [[1 µs]]

edge_machining.post_dist 200000 [0.1µm]

edge_machining.post_feed 333333 [µm/sec]

edge_machining.disable_feed_adaption 0

edge_machining.mode 0

#

Additional information

- Enable / disable (P-CHAN-00220)

- Critical bend angle (P-CHAN-00221)

- Distance before the edge (P-CHAN-00222)

- Feed before edge (P-CHAN-00223)

- Waiting time in edge (P-CHAN-00224)

- Distance after the edge (P-CHAN-00225)

- Feed rate after the edge (P-CHAN-00226)

- Switching feed rate adjustment (P-CHAN-00300)

- Edge detection mode (P-CHAN-00301)