Configuring the workspace

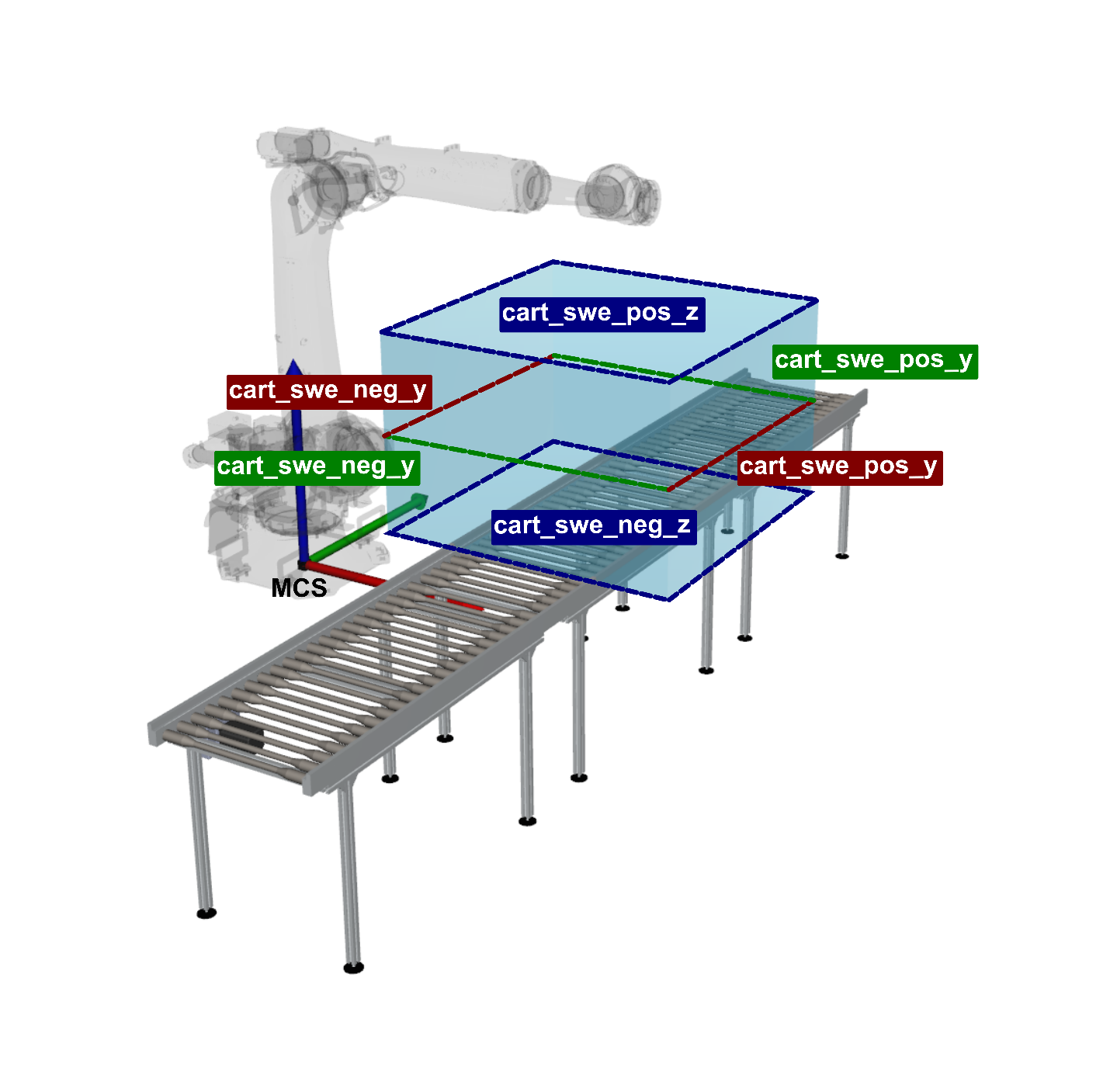

The workspace for conveyor tracking is a cuboid. The cuboid is described in the machine coordinate system (MCS) using P-CHAN-00859 to P-CHAN-00864 as shown in the figure below.

The parameters describe the upper and lower workspace limits in the axes X, Y and Z of the MCS. The workspace cannot be rotated. This is why the workspace axes run parallel to the MCS axes.

Notice

If the parameters P-CHAN-00859 - P-CHAN-00864 are not configured, the configured software limit switches (P-AXIS-00177 / P-AXIS-00178) of the first three axes are used to define the workspace.

This is why the workspace limits must always be configured when a kinematic transformation is used.

The function for monitoring workspace limits, see “Monitoring the workspace limit in the opposite conveying direction”. is only active while synchronisation with the conveyor system is active.